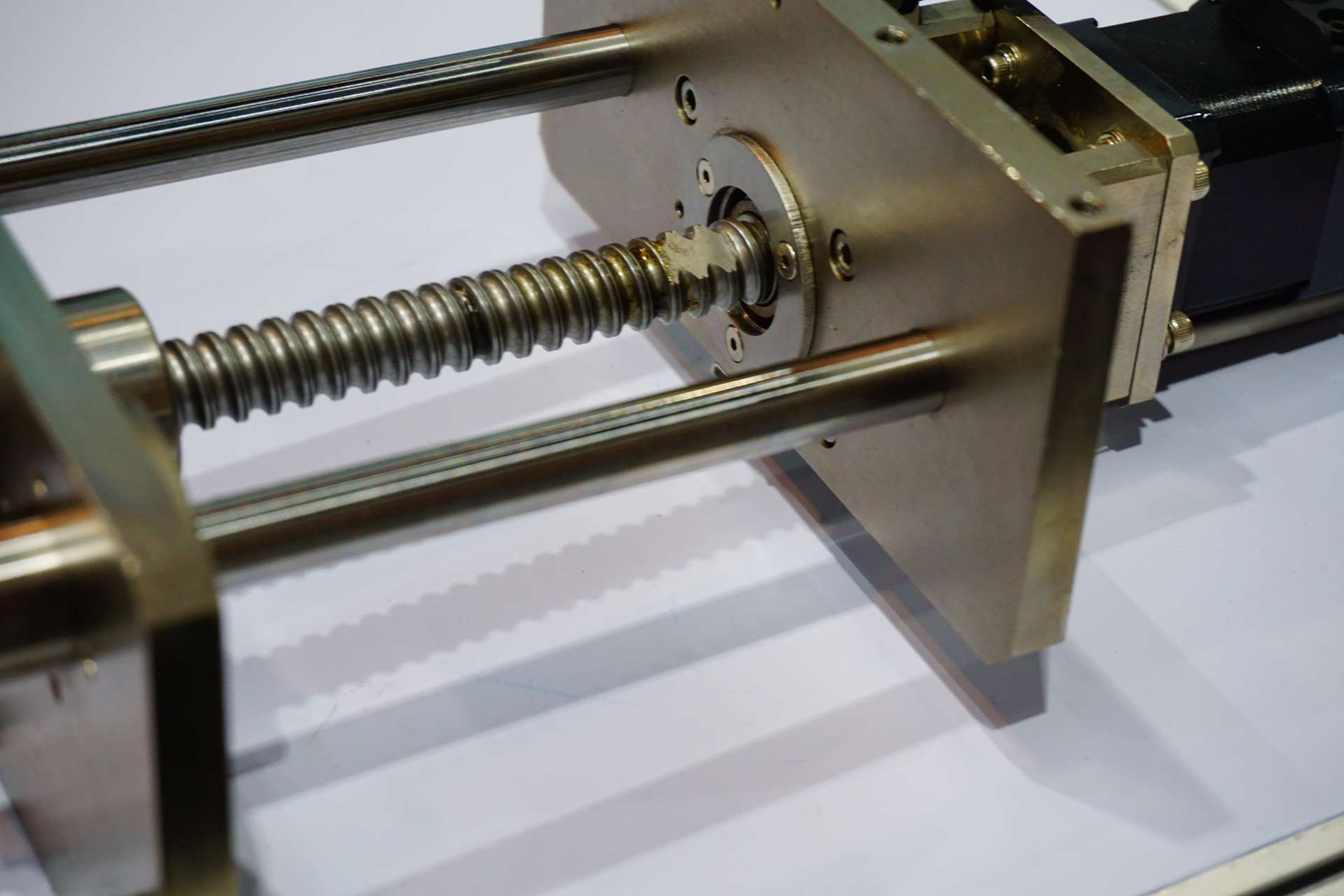

Worn Gear Teeth Signs

What are the common causes of worn gear teeth in mechanical systems?

The common causes of worn gear teeth in mechanical systems include lack of lubrication, misalignment, overloading, and poor maintenance practices. When gears operate without proper lubrication, the friction between the teeth increases, leading to accelerated wear and eventual failure of the gear system.