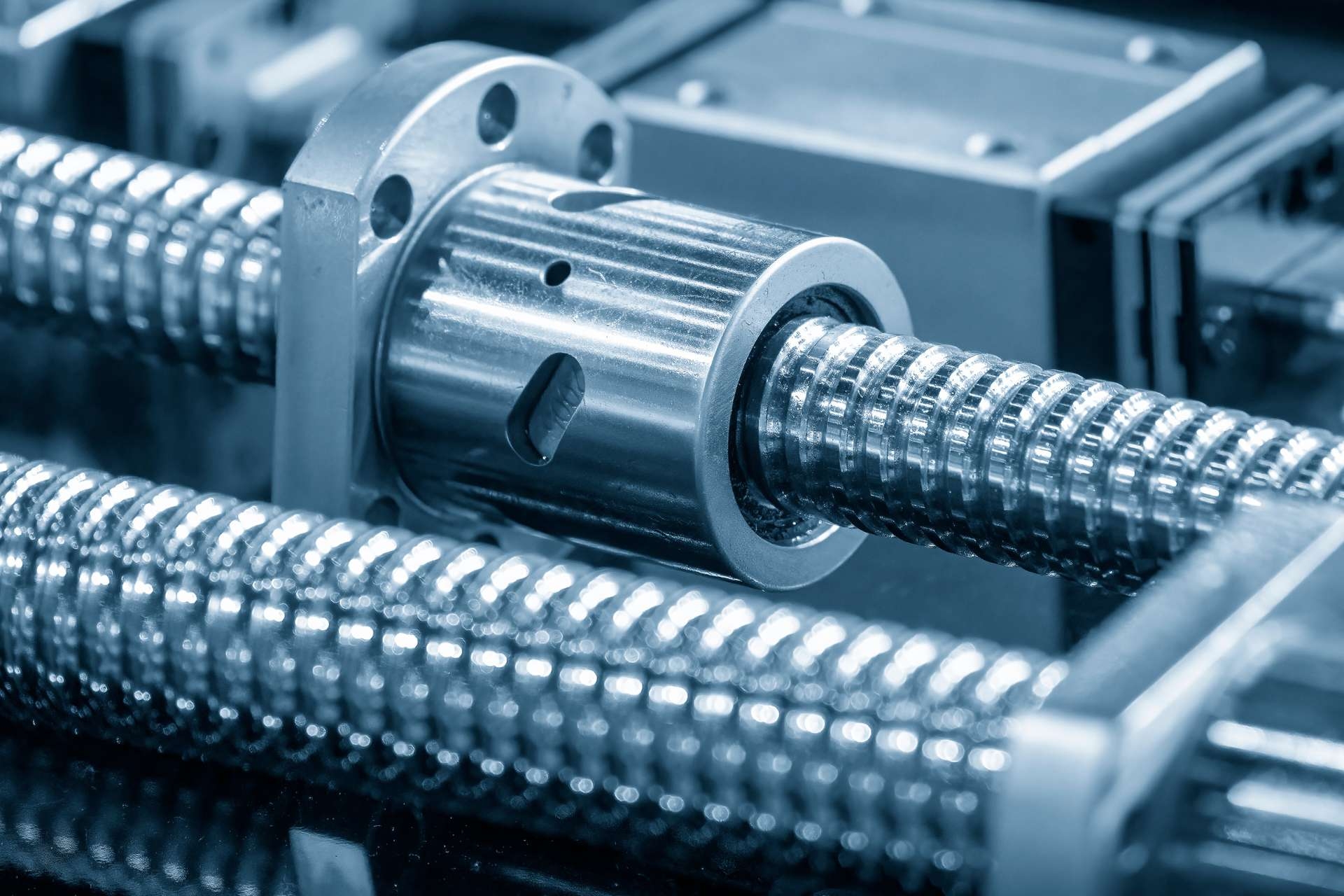

Oil Contamination in Gearbox

How does oil contamination in a gearbox affect the overall performance of the equipment?

Oil contamination in a gearbox can significantly impact the overall performance of the equipment. Contaminants such as dirt, metal particles, and water can cause increased friction, leading to wear and tear on the gears. This can result in decreased efficiency, increased heat generation, and ultimately, premature failure of the gearbox.