Excessive Vibration in Extruder Gearbox

How can excessive vibration in the extruder gearbox affect the quality of the final product?

Excessive vibration in the extruder gearbox can have a detrimental impact on the quality of the final product. The vibrations can lead to inconsistencies in the extrusion process, resulting in variations in product dimensions, surface finish, and overall quality. This can ultimately lead to product defects and increased scrap rates, affecting the overall efficiency and profitability of the manufacturing process.

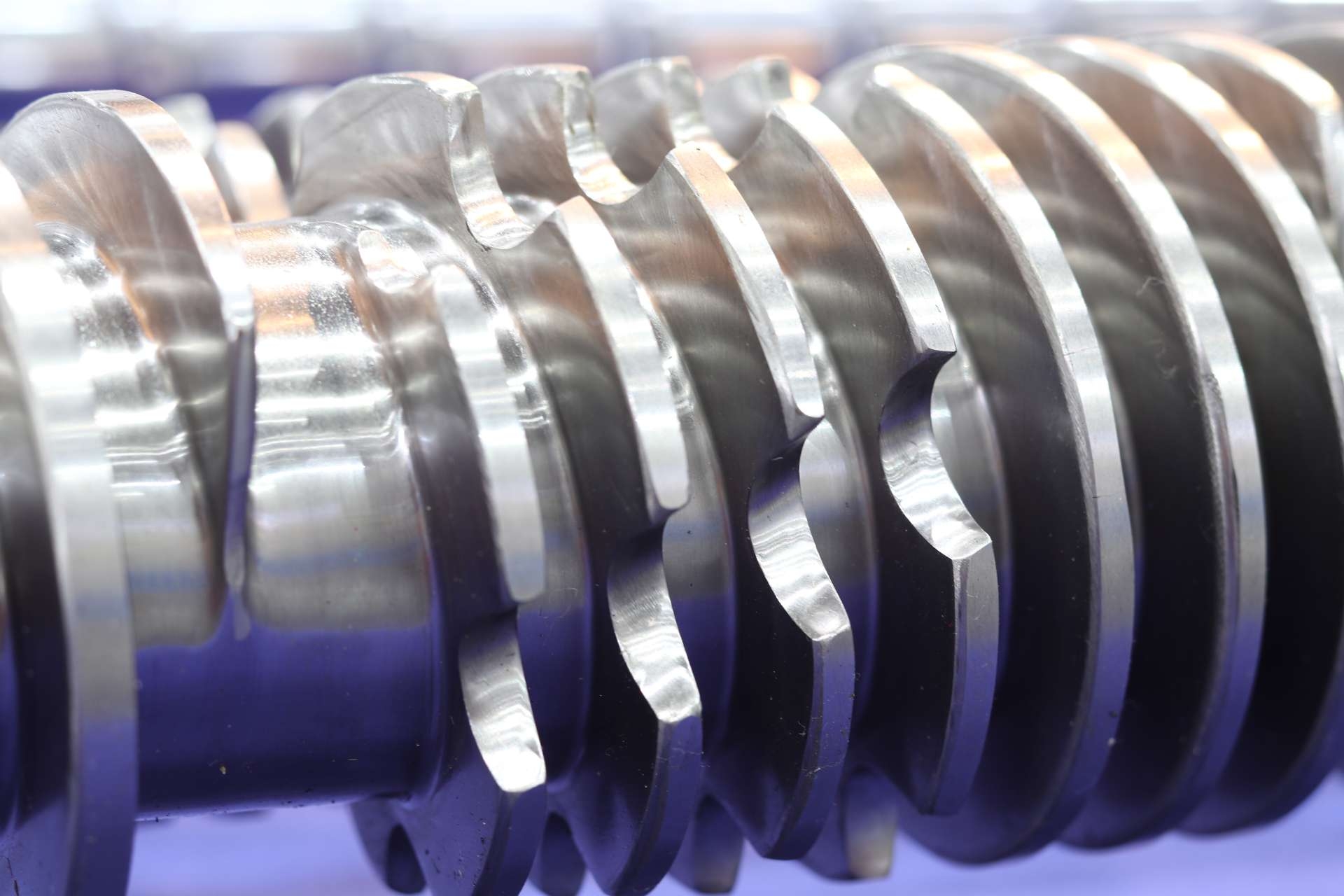

Common Signs of Wear and Tear in Extruder Gearboxes