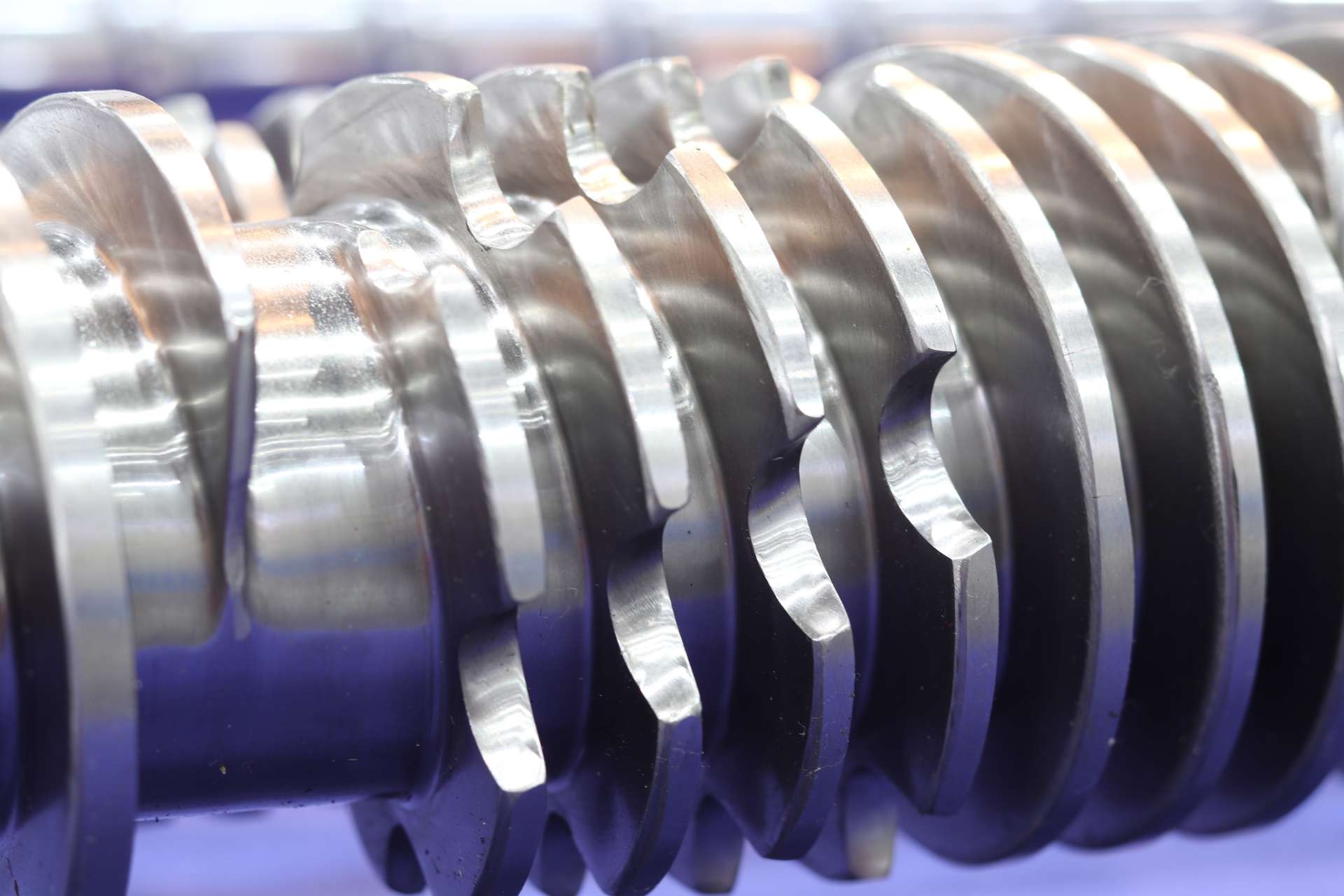

Abnormal Gearbox Backlash

How does abnormal gearbox backlash affect the overall performance of a vehicle?

Abnormal gearbox backlash can significantly impact the overall performance of a vehicle by causing issues such as gear slipping, difficulty shifting, and increased noise during operation. This can lead to a decrease in fuel efficiency, acceleration, and overall driving experience. The abnormal movement of the gears can also put additional strain on other components of the transmission system, potentially leading to more serious mechanical problems over time.