Gearbox Shaft Wear Patterns

What are the common wear patterns seen on gearbox shafts?

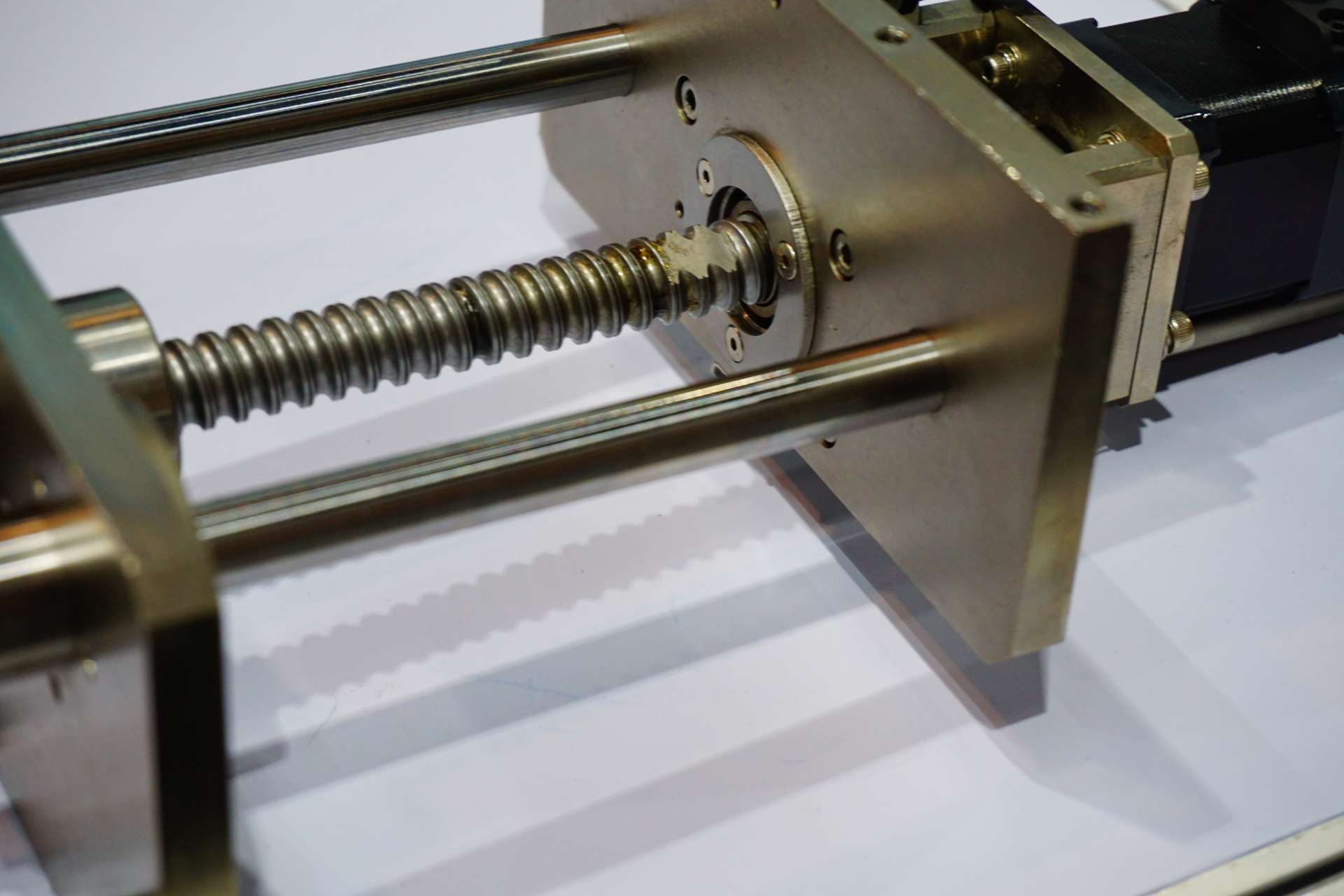

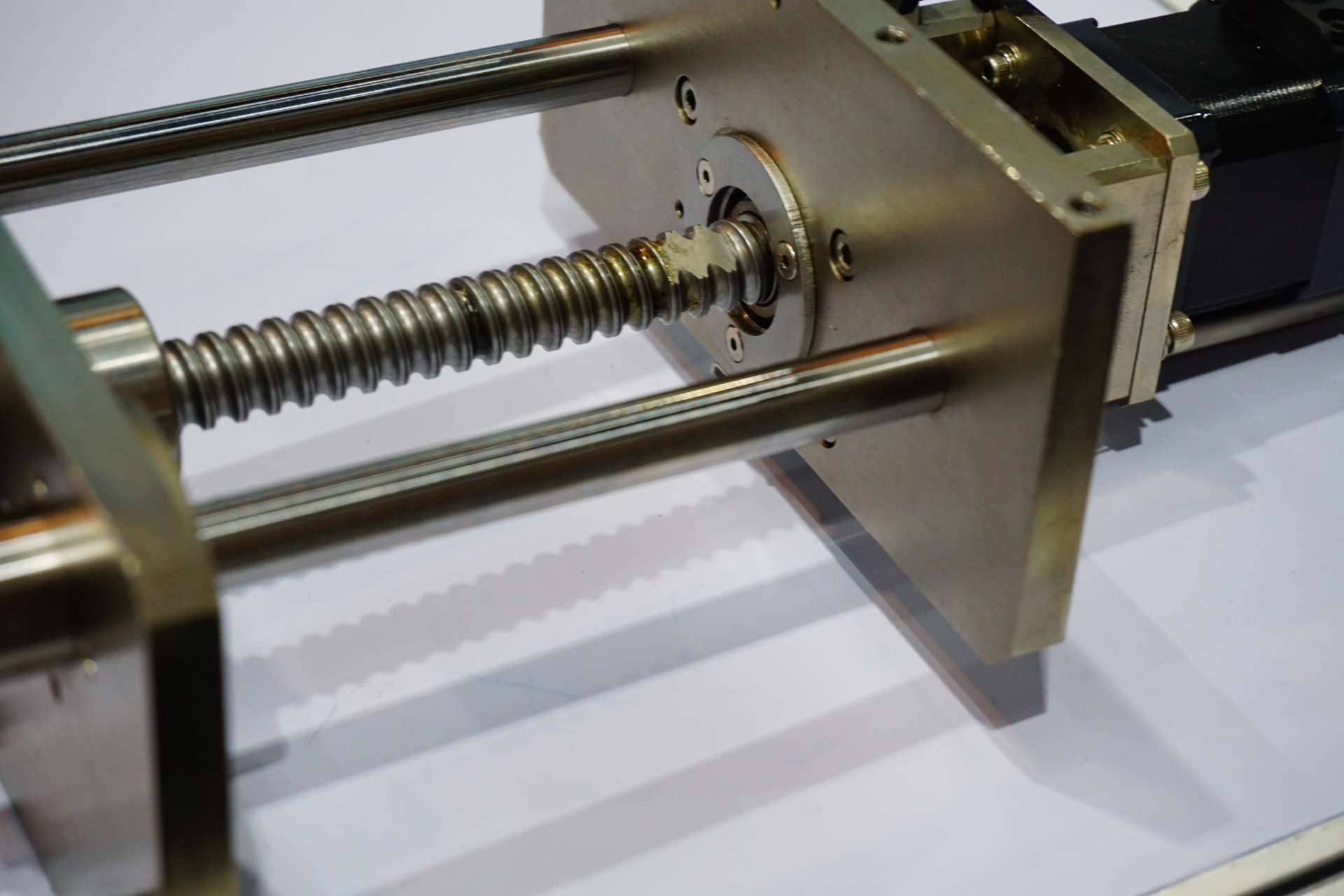

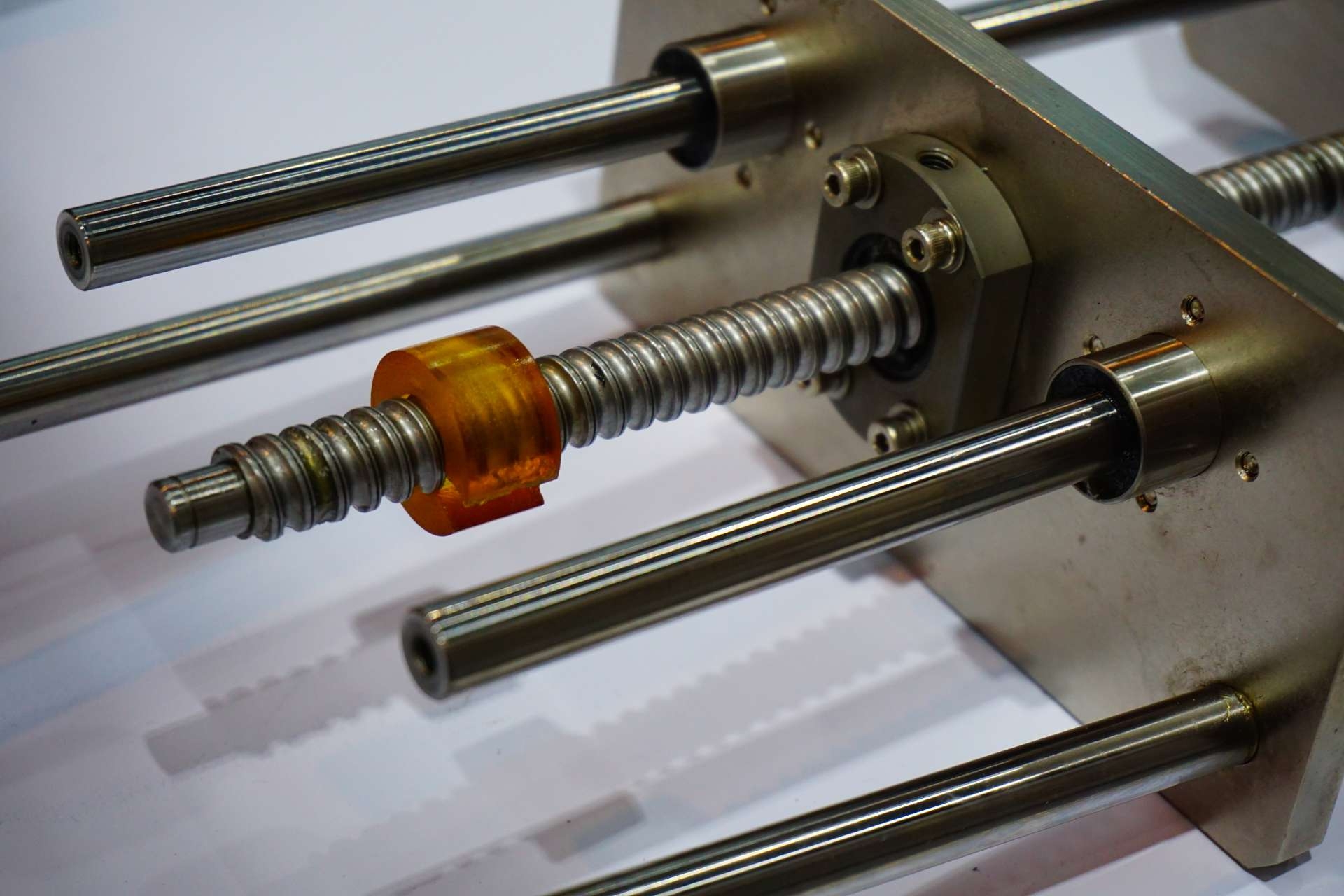

Common wear patterns seen on gearbox shafts include pitting, scoring, and spalling. Pitting is characterized by small craters or holes on the surface of the shaft, while scoring refers to scratches or grooves caused by friction. Spalling occurs when small pieces of the shaft material break off, leading to a rough and uneven surface texture.