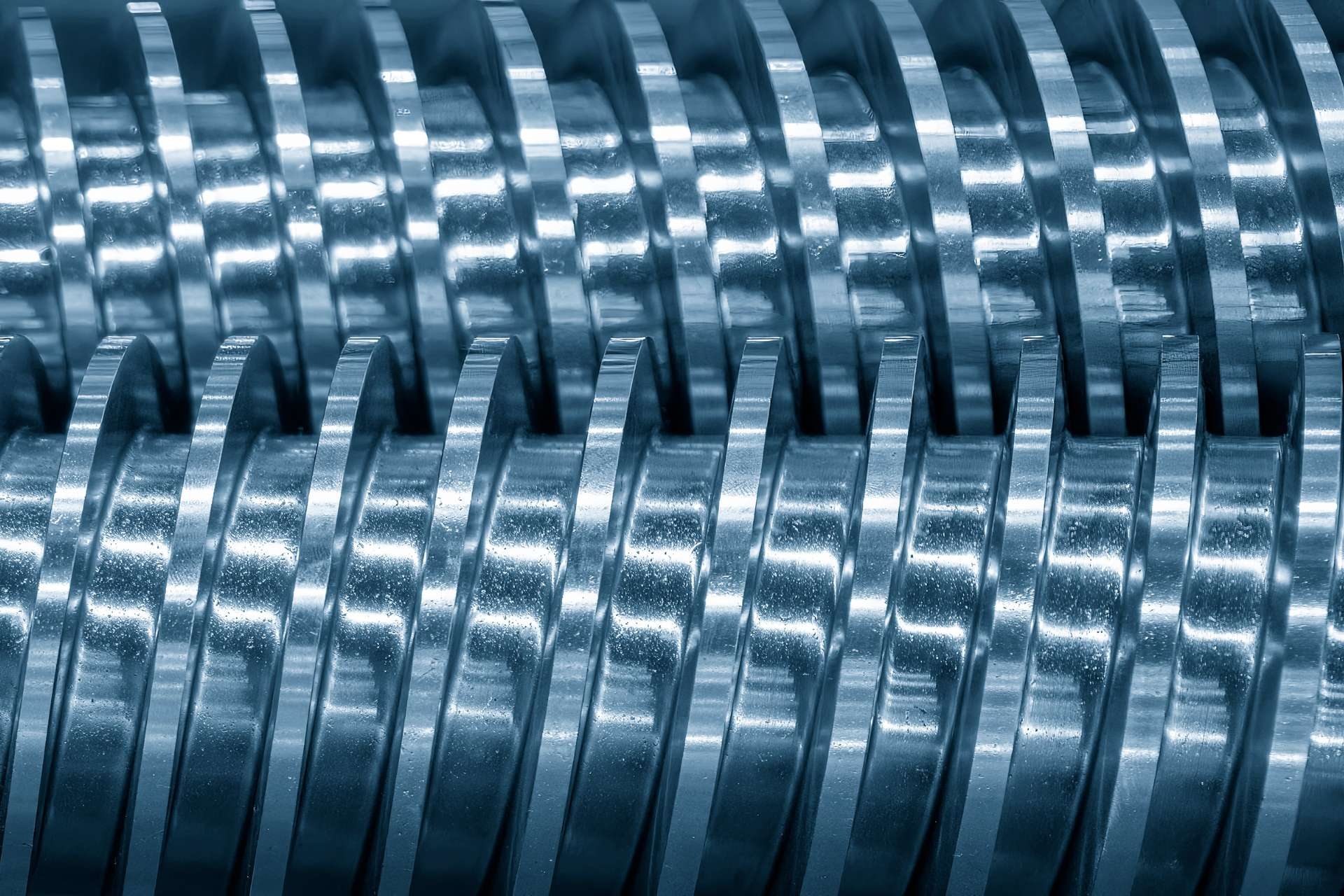

Gearbox Bearing Wear Patterns

What are the common wear patterns seen in gearbox bearings due to misalignment?

Common wear patterns in gearbox bearings due to misalignment include uneven wear on the inner or outer race, brinelling (indentations on the raceways), and increased vibration leading to premature fatigue. Misalignment can cause the bearings to operate at an angle, resulting in excessive stress on certain areas, leading to these specific wear patterns.