Gearbox Shaft Endplay Symptoms

What are the common symptoms of excessive gearbox shaft endplay?

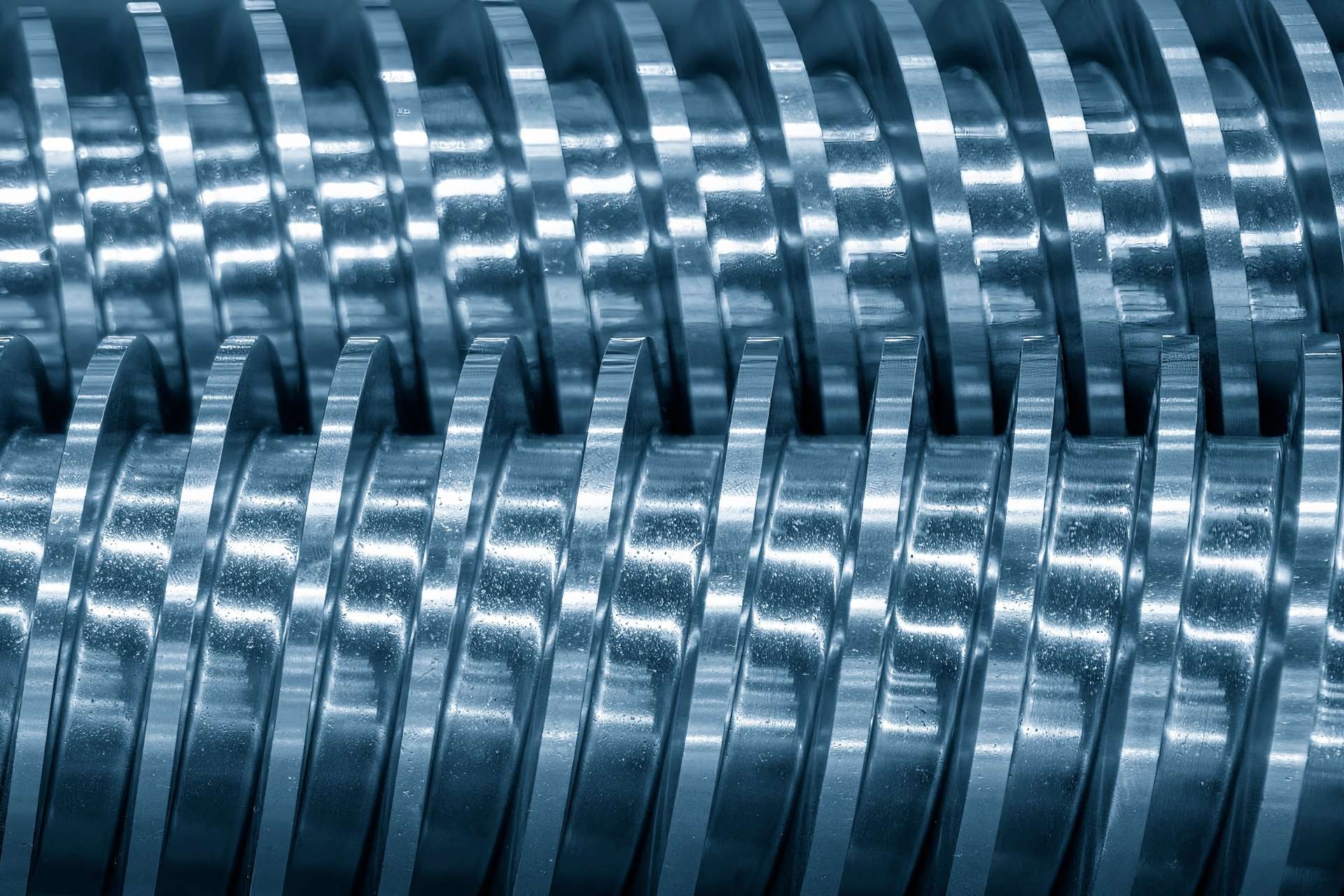

Excessive gearbox shaft endplay can manifest in various symptoms, including abnormal noises coming from the transmission, difficulty shifting gears, vibrations felt while driving, and potential leaks of transmission fluid. These symptoms can indicate that there is too much movement in the gearbox shaft, which can lead to further damage if not addressed promptly.