Gearbox Housing Cracks

What are the common causes of gearbox housing cracks in vehicles?

Gearbox housing cracks in vehicles can be caused by a variety of factors, including excessive heat, overloading, poor maintenance, manufacturing defects, and impact damage. These cracks can develop over time due to stress and strain on the gearbox housing, leading to potential structural weaknesses.

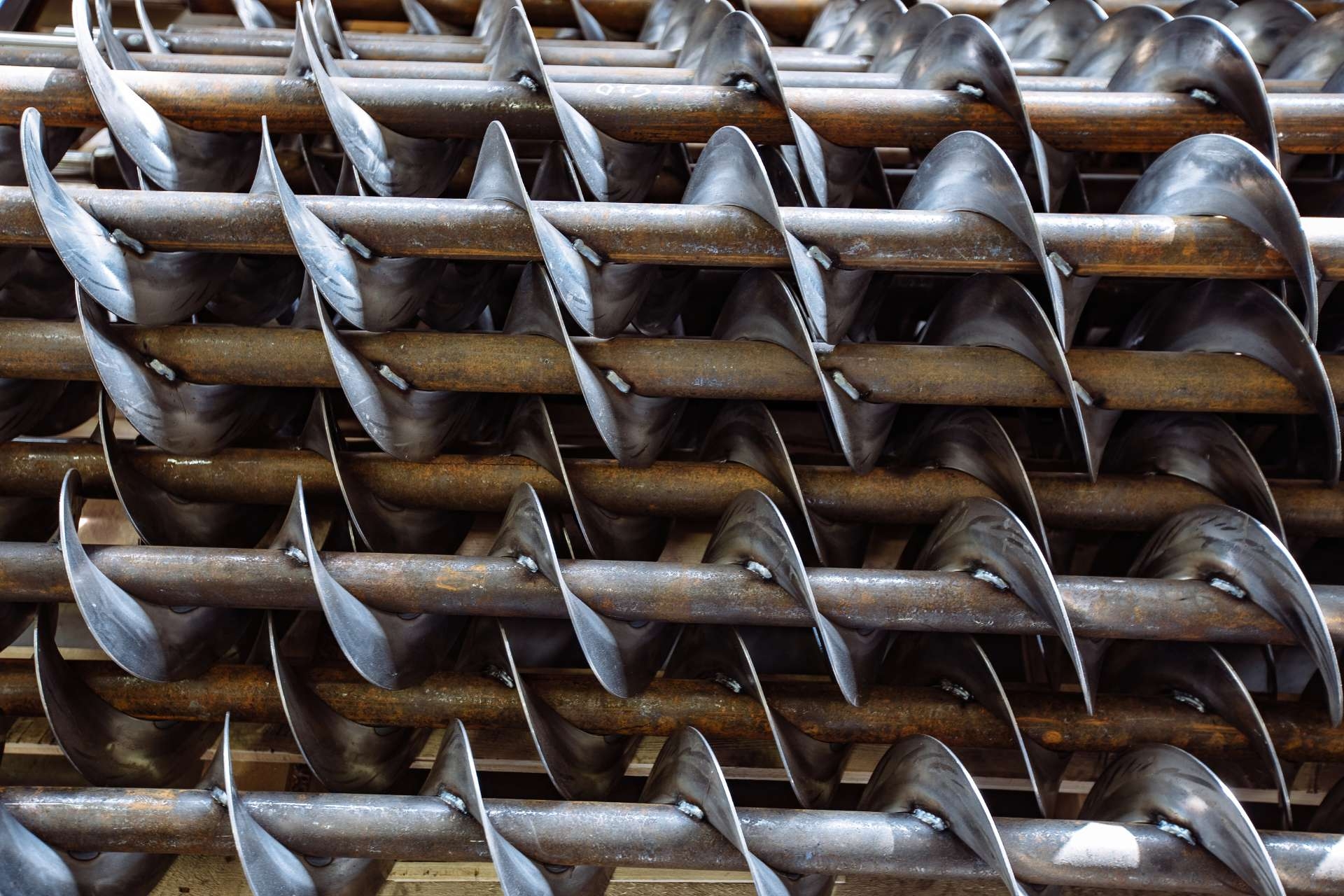

Common Signs of Wear and Tear in Extruder Gearboxes