Gearbox Seal Wear Indicators

What are the common signs of gearbox seal wear?

Common signs of gearbox seal wear include oil leaks around the gearbox, low gearbox oil levels, unusual noises coming from the gearbox, and difficulty shifting gears. These indicators can point to potential issues with the gearbox seals that need to be addressed promptly to prevent further damage.

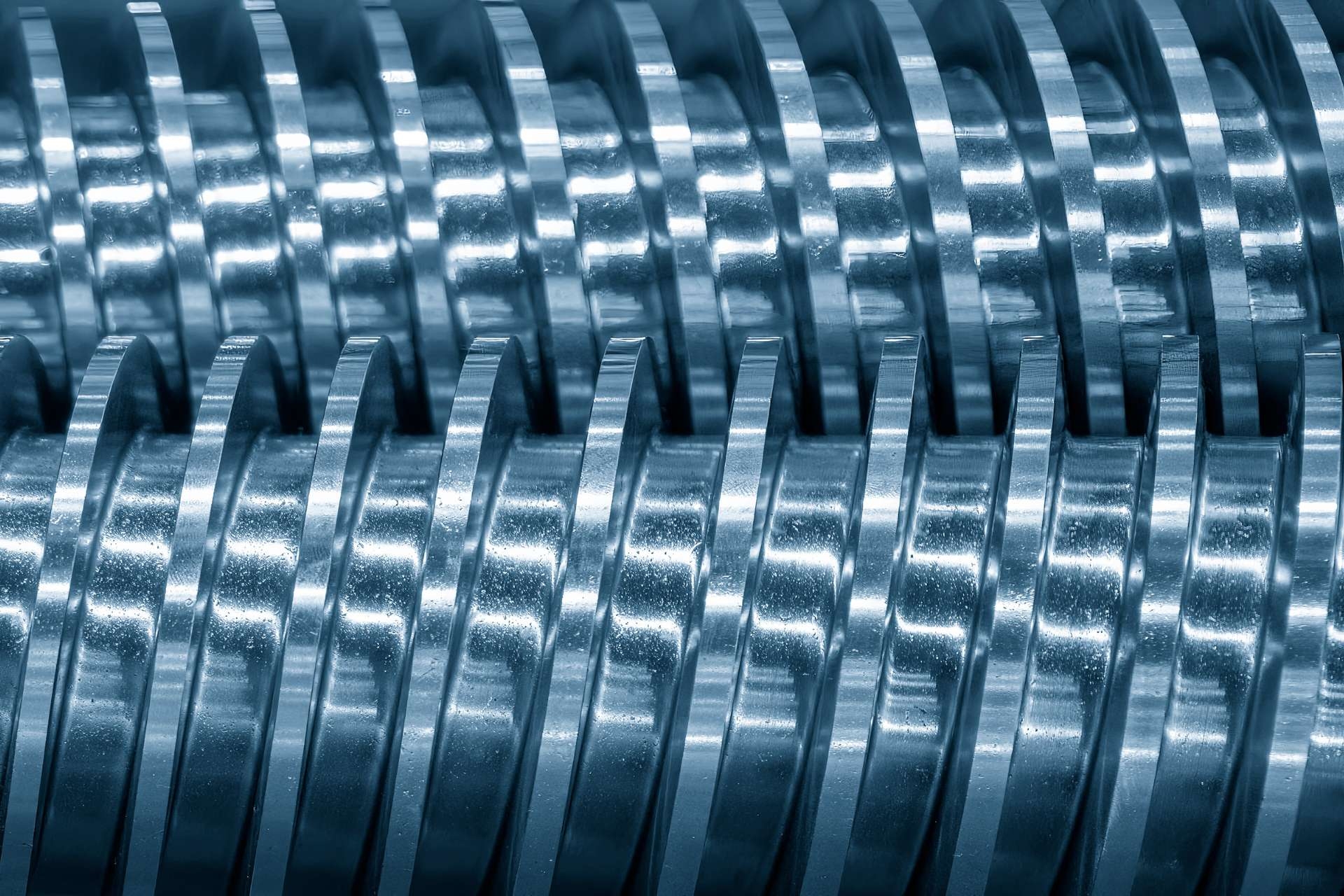

Common Signs of Wear and Tear in Extruder Gearboxes