Excessive Gearbox Backlash

How does excessive gearbox backlash affect the overall performance of a machine?

Excessive gearbox backlash can significantly impact the overall performance of a machine by causing inaccuracies in motion control, reduced efficiency, increased wear and tear on components, and potential safety hazards. The presence of excessive backlash can lead to issues such as vibration, noise, and decreased precision in the operation of the equipment, ultimately affecting the quality of the end product.

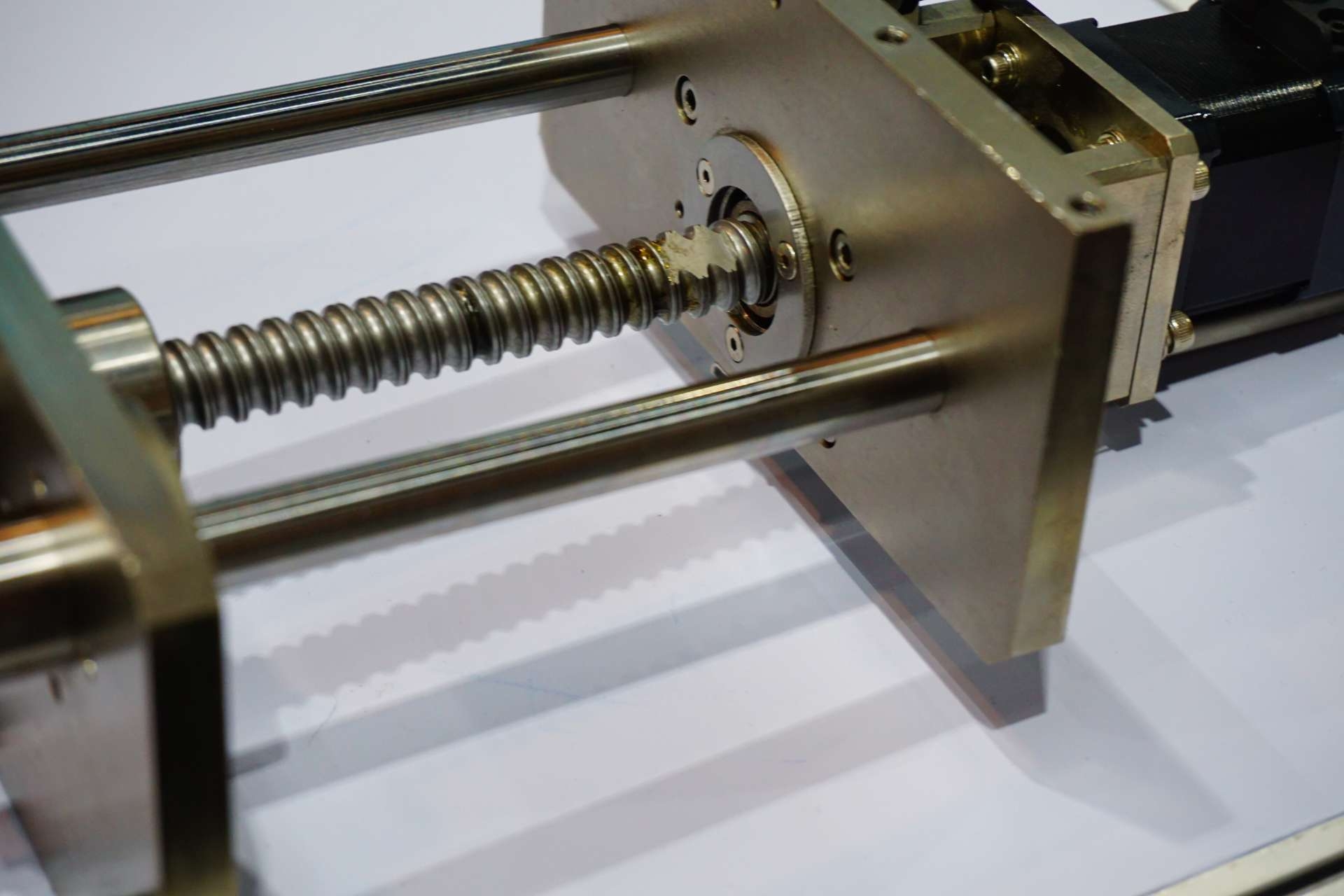

Common Signs of Wear and Tear in Extruder Gearboxes