Reduced Gearbox Efficiency Indicators

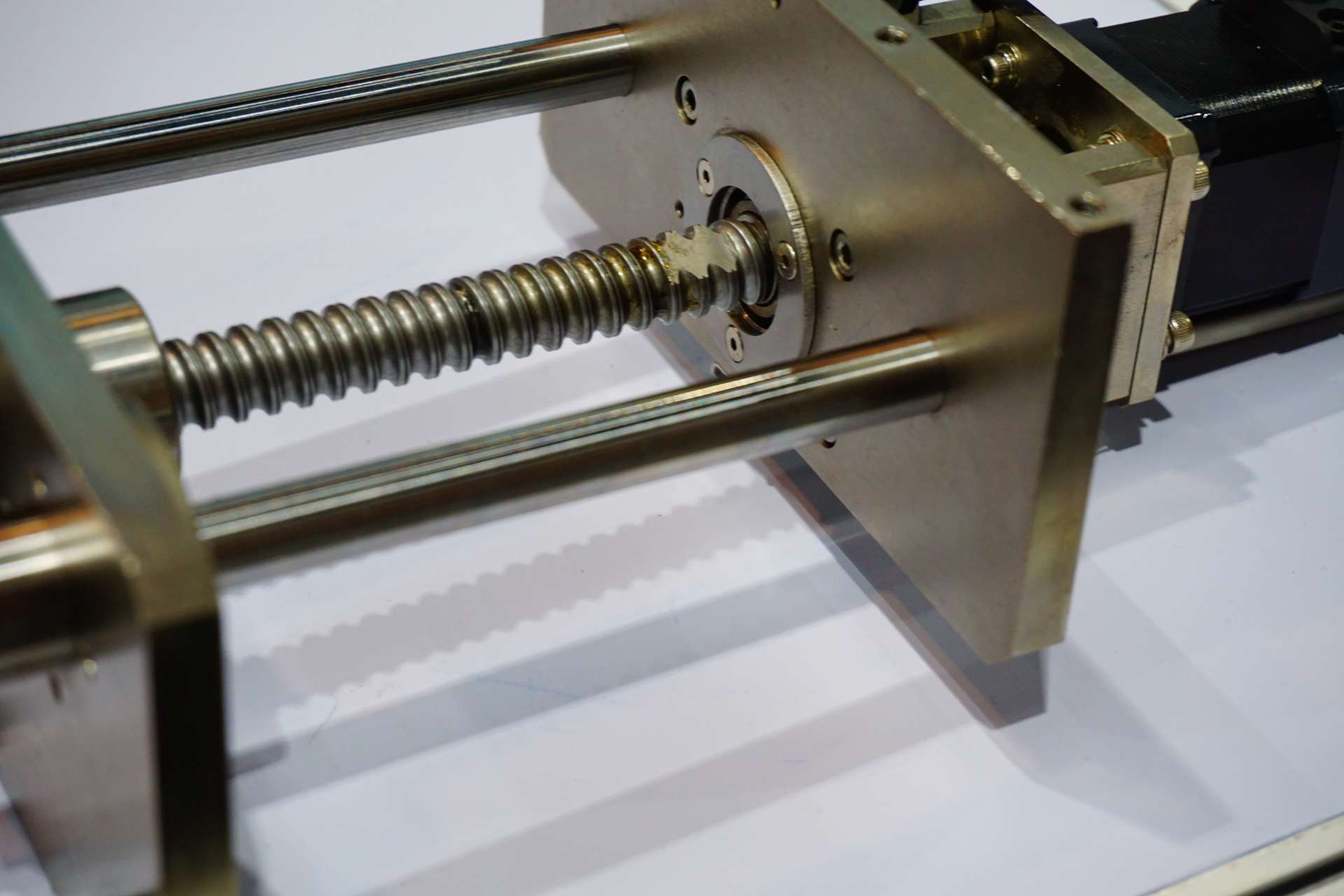

How does friction impact the efficiency of a gearbox?

Friction plays a significant role in impacting the efficiency of a gearbox. When there is excessive friction between the moving parts of the gearbox, it can lead to energy loss and decreased performance. Friction causes heat to build up, which can result in wear and tear on the gears, ultimately reducing the overall efficiency of the gearbox.

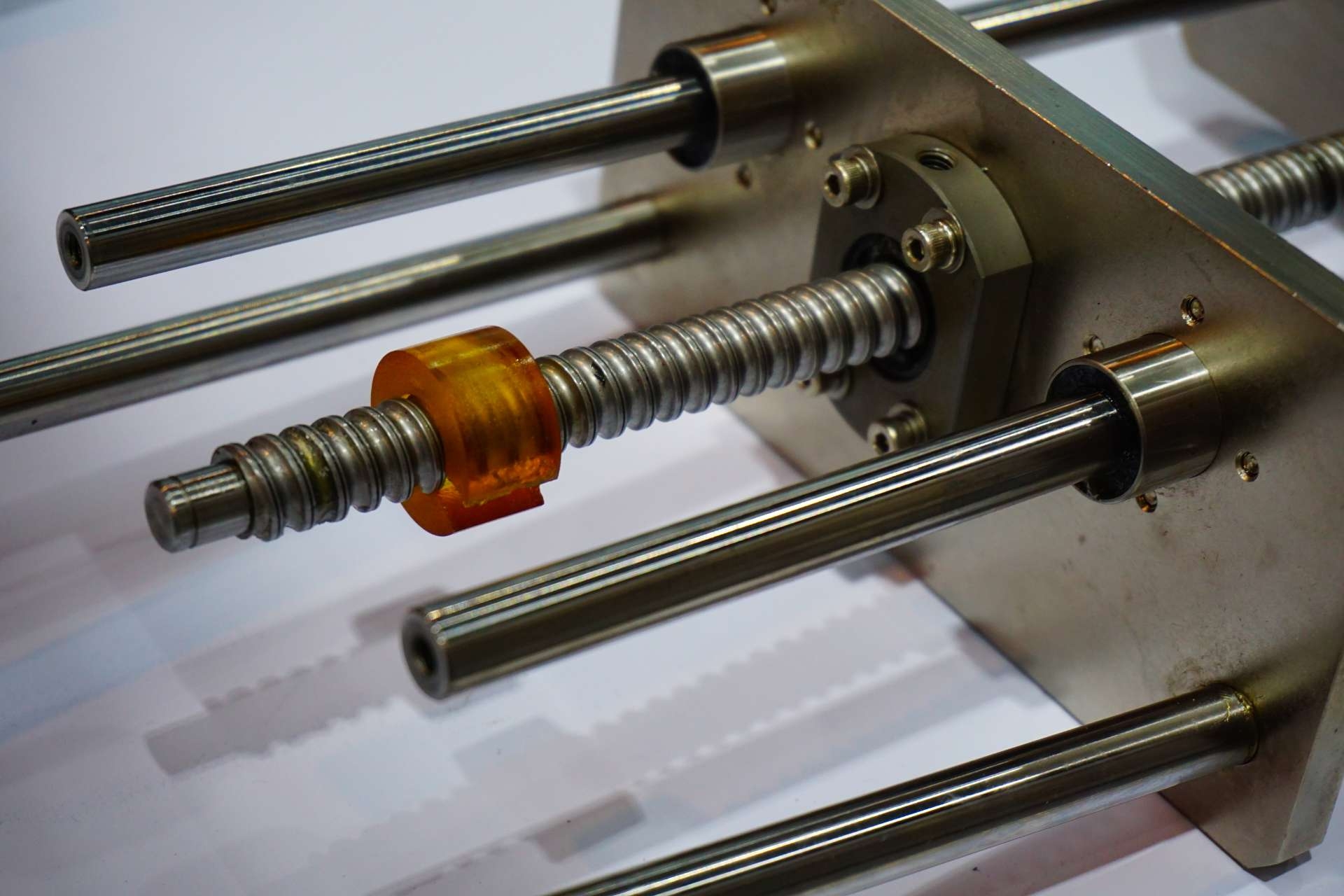

Common Signs of Wear and Tear in Extruder Gearboxes