Lubrication Failure Effects

What are the common signs of lubrication failure in machinery?

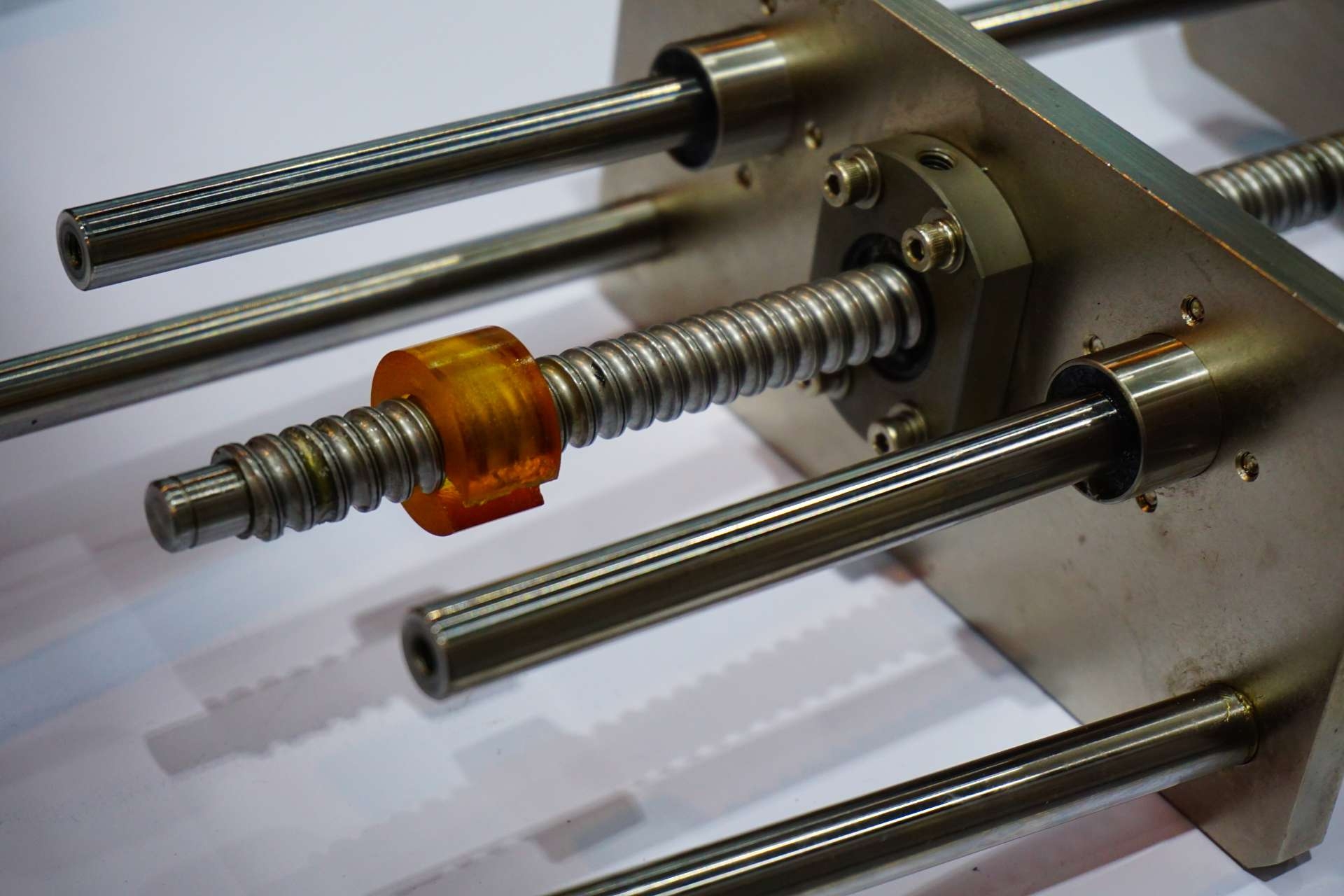

Common signs of lubrication failure in machinery include increased noise levels, elevated operating temperatures, vibration, and visible signs of wear on components. When lubrication breaks down or is insufficient, it can lead to metal-to-metal contact, causing friction and wear that can ultimately result in equipment failure.