Grinding Sounds in Gearbox

What are the common causes of grinding sounds in a gearbox?

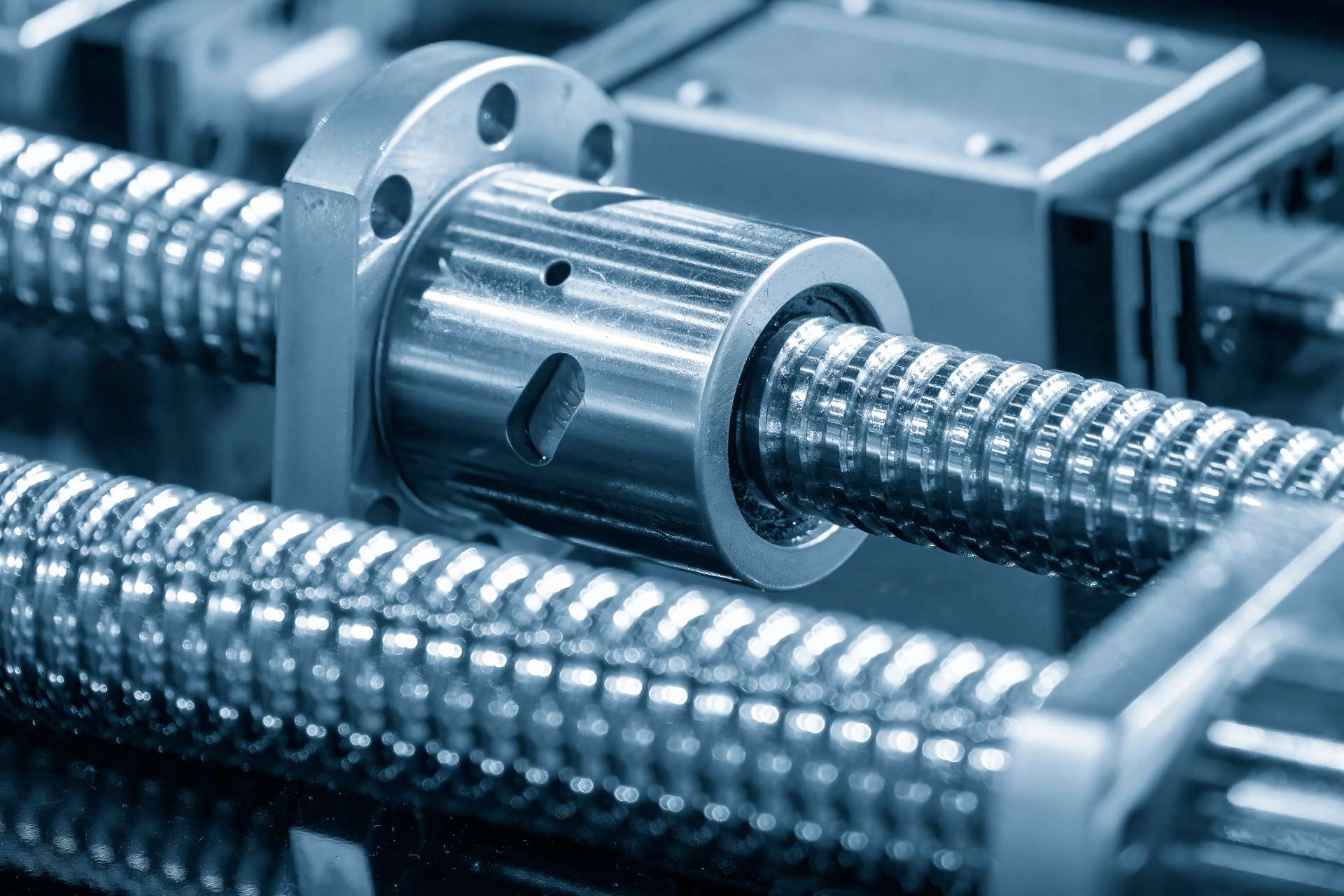

Grinding sounds in a gearbox can be caused by various factors, including worn-out gears, lack of lubrication, or foreign particles entering the gearbox. These issues can lead to the gears rubbing against each other, creating the grinding noise that indicates a problem within the gearbox.