Wedge vs Ball Bonding: Which Technique Reigns Supreme?

Introduction

In the area of semiconductor packaging and microelectronic assembly, two dominant twine bonding strategies stand out: wedge bonding and ball bonding. Both strategies are critical in making sure sturdy interconnections between chips and substrates, however they come with certain features, benefits, and programs. This article delves deep into the intricacies of these two cord bonding systems, proposing a comprehensive research to verify which components reigns ultimate in quite a lot of scenarios. Whether you’re a pro engineer or simply opening your event in twine bonding generation, this guide will equip you with significant insights.

What is Wire Bonding?

Wire bonding is a technique used to create electrical connections among semiconductor instruments and their packages. It involves the use of skinny wires—in general made up of gold, aluminum, copper, or silver—which might be thermally or ultrasonically bonded to pads on a chip and substrate. The cord bonding procedure is a very powerful for high-overall performance electronics because it instantly affects reliability, functionality, and usual software high quality.

The Wire Bonding Process Explained

The cord bonding manner may well be broken down into countless key steps:

By knowing how twine bonding works, you can actually have an understanding of its extreme role in sleek electronics production.

Types of Wire Bonding Techniques

Wire bonding encompasses quite a number techniques tailor-made for specified purposes:

- Ball Bonding: Involves forming a ball at the conclusion of the wire ahead of making a bond.

- Wedge Bonding: Utilizes a wedge-formed software to create bonds without forming a ball on the give up.

- Ribbon Bonding: Uses wider ribbons in preference to conventional wires for large floor components.

Each model has its precise set of features that influence functionality in one of a kind situations.

Wedge vs Ball Bonding: A Comparative Overview

When evaluating wedge vs ball bonding options, or not it's needed to investigate their center transformations:

1. Bond Formation Mechanism

-

Ball Bonding:

- Begins with heating the cord's stop to model a small ball.

- The ball is then pressed against the bond pad utilizing ultrasonic vitality to create a strong attachment.

-

Wedge Bonding:

- Uses a wedge instrument that presses down at the wire without forming a pre-bonded sphere.

- Bonds are created through mechanical pressure blended with warm (thermosonic) or ultrasonic vitality.

2. Material Compatibility

Each method favors specific fabrics:

- Ball bonding predominantly uses gold by way of its ideal conductivity.

- Wedge bonding can utilize aluminum or copper wires effortlessly.

3. Applications and Industry Use Cases

Both techniques in finding their area of interest throughout varied sectors:

-

Ball Bonding:

- Widely used in microelectronics like IC packaging via its compatibility with positive pitch packages.

-

Wedge Bonding:

- Preferred in force modules and car electronics wherein larger pads are widely wide-spread.

four. Cost Consideration

Cost plays an fundamental role in Click here for more info choosing among those procedures:

| Feature | Ball Bonding | Wedge Bonding | |------------------|--------------------------|---------------------------| | Material Cost | Higher (Gold) | Lower (Aluminum/Copper) | | Equipment Cost | Typically better | Generally curb |

5. Reliability Factors

Reliability is paramount in digital functions:

- Ball bonds tend to demonstrate improved fatigue resistance less than thermal cycling circumstances.

- Wedge bonds give remarkable moisture resistance because of the their lessen stress stages on pads.

Detailed Analysis of Wedge Bonding Process

What Makes Wedge Bonding Unique?

Wedge bonding stands out by means of its essential but potent mechanism for developing strong connections between chips and substrates without having a pre-bonded sphere:

Key Advantages

Applications

Wedge bonding finds software across multiple industries which include:

- Automotive electronics

- Power modules

- Aerospace components

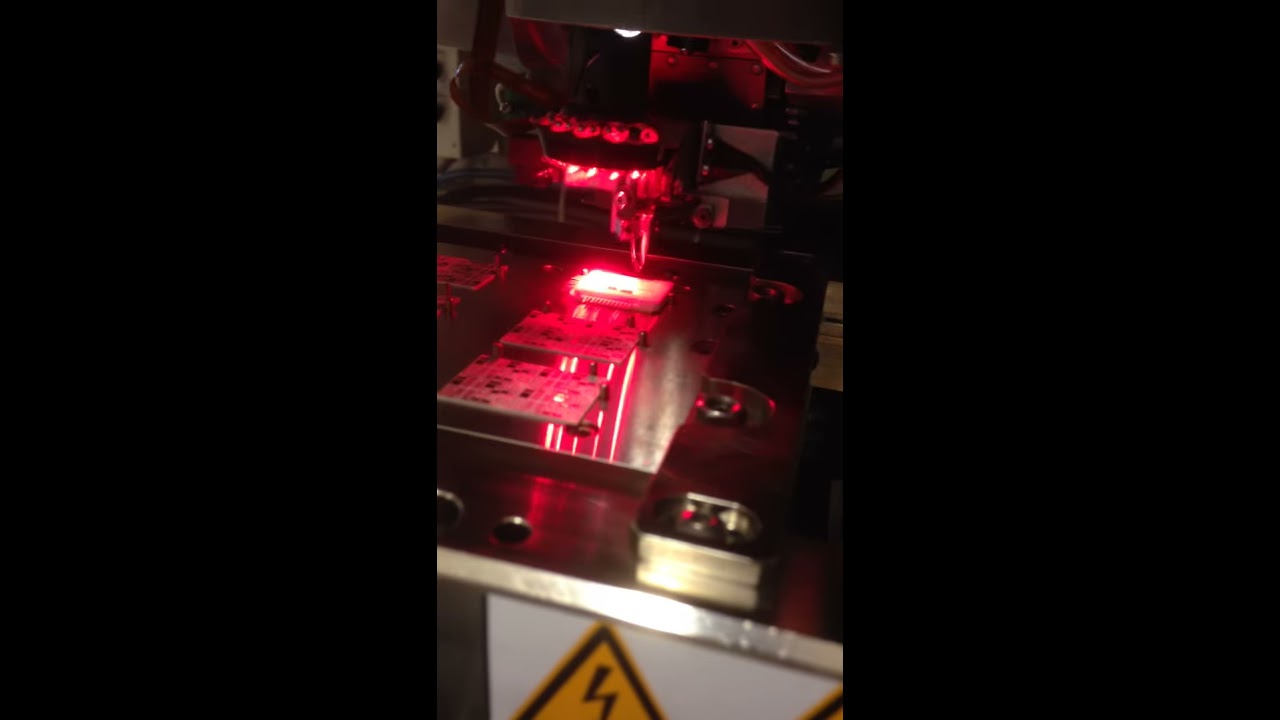

Understanding Wedge Wire Bonding Machines

The success of wedge bonding closely relies on complicated apparatus designed primarily for this objective:

In-depth Look at Ball Bonding Process

What Defines Ball Bonding?

Ball bonding is by and large desired in top-density applications where house is restricted but performance wants continue to be top:

Key Features

Applications

Ball bonding excels relatively in sectors similar to:

- Microelectronics

- Telecommunications

- High-frequency RF applications

Exploring Ball Wire Bonding Machines

To acquire gold standard performance throughout ball bonding tactics, really good machinery is applied:

Evaluating Wire Bond Quality Control Measures

Quality regulate all the way through each approaches won't be overstated as it in an instant impacts yield charges and product reliability:

1. Inspection Methods

Various inspection concepts be sure that that bonds meet stringent industry standards:

| Inspection Method | Description | |-------------------------|--------------------------------------------------| | Visual Inspection | Manual assessments with the aid of operators via magnification | | Pull Test | Evaluates the energy of particular person bonds | | Shear Test | Assesses adhesive strength among layers |

2. Common Failure Modes

Understanding knowledge failure modes enables mitigate disadvantages related to either technology:

For Ball Bonds:

- Incomplete Bonds

- Oxidation Issues

For Wedge Bonds:

- Heel Cracking

- Pad Damage

Implement rigorous inspections submit-technique to seize concerns early until now they have an impact on downstream production ranges.

Advantages and Disadvantages of Each Technique

When finding out among wedge vs ball bonding, take into accounts these execs and cons which may influence your creation line selections critically:

Advantages of Ball Bonding

Disadvantages of Ball Bonding

Advantages of Wedge Bonding

Disadvantages of Wedge Bonding

FAQs About Wedge vs Ball Bonding Techniques

Here are a few most likely requested questions on the topic of those two indispensable concepts:

1. What’s the known difference between wedge and ball bonding?

The main big difference lies of their bond formation mechanism; ball bonding uses a melted sphere while wedge employs direct tension with out pre-formations ensuing in wonderful benefits established on application necessities!

2. When needs to I select one strategy over an additional?

If you are looking at compact designs regarding effective pitches—select ball bonds! However if running inside of vitality modules requiring longevity—wedge can even serve first-rate right here instead!

3. Are there confident components best exact for one manner?

Yes certainly! Gold works most suitable with balls even as aluminum/copper excel beneath wedges! Make definite you prefer accurately headquartered upon your project requirements!

4. How does each components impact lengthy-term reliability?

Generally speakme—a nicely-achieved ball bond exhibits most useful fatigue resistance! While wedges convey significant moisture coverage guaranteeing toughness regardless!

5.Who promises classes materials on those tactics?

Many universities offer classes along such a big amount of on-line structures hosting tutorials & webinars centred explicitly upon modifying competencies around those main technologies!!

Conclusion

Choosing among wedge vs ball bonding in some way boils down personal desire dictated by way of specific task parameters—concerns akin to subject material decision,rate factors,and wanted overall performance effect play pivotal roles influencing this determination-making task immensely!

Both processes have enjoyable strengths; to that end information your utility’s extraordinary calls for permits you leverage either system with no trouble while maximizing productivity yields at some point of production cycles forward!