Understanding the Wire Bonding Process: A Comprehensive Guide

Introduction

The wire bonding process is a principal method in semiconductor manufacturing and electronic meeting. It serves as a very important connection between included circuits (ICs) and their substrates, allowing electrical signs to move seamlessly. With the immediate progress of electronics in a range of industries resembling automobile, aerospace, and medical units, knowing the intricacies of wire bonding technological know-how has by no means been extra priceless.

In this finished support, we're going to delve into diverse points of wire bonding which include its methodologies, equipment, packages, reliability exams, and long term developments. By the end of this newsletter, you can still have an intensive realizing of the wire bonding course of and its value in innovative electronics.

What is Wire Bonding?

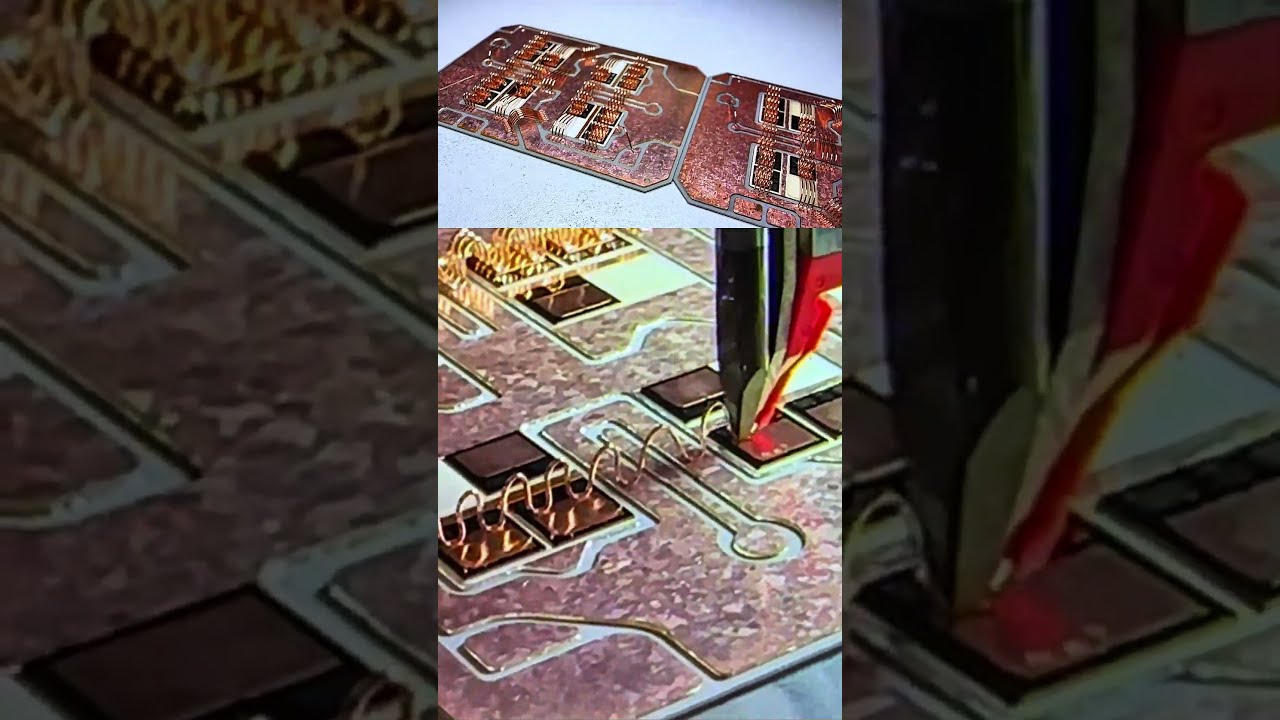

Wire bonding is one way used to create electric connections among semiconductor units and their applications or substrates the use of exceptional wires. The process routinely contains two universal methods: ball bonding and wedge bonding. Each system has its personal specific applications relying on components like materials homes and design standards.

How Wire Bonding Works

Wire bonding employs mechanical force and heat to sort bonds among metal wires—recurrently gold, aluminum, or copper—and pads on silicon chips or different surfaces. The option of drapery most likely relies upon on can charge concerns, thermal conductivity, and efficiency requisites.

Understanding the Wire Bonding Process: A Comprehensive Guide

The Importance of Wire Bonding Technology

Wire bonding know-how performs a pivotal position in making certain secure connections inside of digital devices. As technology advances closer to miniaturization and greater complexity, superb cord bonding suggestions are primary for top-functionality functions.

Different Types of Wire Bonding Techniques

- This way consists of developing a small ball at the quit of a wire by melting it with warm prior to making touch with the bond pad.

- Wedge bonding utilizes a flat device to press the cord towards the substrate with out heating it.

- Ribbon bonding employs broader strips of metallic rather than ordinary circular wires for extra floor section touch.

Wire Bonding Equipment: Key Components

- Wire Bonding Machine: The center of the operation where automation takes vicinity.

- Bonding Capillary Tool: Essential for positioning the cord accurately.

- Ultrasonic Generator: Supplies ultrasonic potential at some stage in assured kinds of bonds.

Wire Bonding Applications Across Industries

Wire bonding unearths use in quite a number sectors:

- Automotive Electronics: Ensures solid connections in safe practices strategies.

- Medical Devices: High reliability is paramount for existence-saving equipment.

- Aerospace: Components have got to resist excessive stipulations.

- Consumer Electronics: Mobile instruments require compact preparations.

Wire Bonding Failure Analysis

Understanding manageable failure modes is imperative for recuperating reliability:

Common Failures in Wire Bonding

Failures can appear by amtech wire bonding bond lifting or heel cracks that compromise connectivity. Identifying those considerations early can avoid large losses down the road.

Wire Bonding Reliability Factors

Reliability is stimulated by a couple of motives:

- Environmental controls

- Material choices

- Bond power calibration

Quality Control in Wire Bonding

Implementing stringent first-rate manipulate measures ensures that every one bond meets enterprise concepts. Techniques like visible inspection or computerized bond inspection play main roles right here.

Cost Implications of Wire Bonding Processes

Understanding twine bonding rates can assist organisations make instructed decisions on manufacturing:

- Material bills (gold vs aluminum)

- Labor rates related to guide as opposed to automatic processes

- Maintenance fees for machinery

Comparative Analysis: Gold vs Aluminum Wire Bonding

| Factor | Gold Wire | Aluminum Wire | |---------------------|---------------------------|-----------------------------| | Cost | Higher | Lower | | Oxidation Resistance | Excellent | Moderate | | Thermal Conductivity | Superior | Good |

Best Practices in Wire Bond Design

Proper design principles can reinforce reliability:

Bond Strength Considerations

Achieving most advantageous bond potential calls for cautious calibration of parameters together with power settings at some point of software.

Specialized Techniques in Wire Bonding

Advanced recommendations embrace:

These procedures cater to extraordinary demanding situations posed by way of excessive-density designs.

FAQs approximately Wire Bonding

What parts are widely utilized in cord bonding?

Common constituents embrace gold, aluminum, copper, and silver as a result of their exceptional conductive houses.

How does environmental keep watch over have effects on cord bonding?

Proper environmental controls mitigate disadvantages along with oxidation or illness which may cause mess ups.

What industries profit from twine bonding?

Industries like automotive, clinical instruments, aerospace, person electronics, and telecommunications all depend upon riskless wire bonds for functionality.

How do you practice fine manipulate checks right through wire bonding?

Quality checks can even contain visual inspections, computerized trying out machines for bond integrity assessments (shear tests), and x-ray inspections to stumble on hidden blunders.

What is ribbon bonding? How does it range from common tactics?

Ribbon bonding uses wider strips rather than circular wires permitting more suitable surface subject contact which enhances reliability however may perhaps require really expert gadget.

Can I customize my cord bonding providers?

Yes! Many suppliers provide tradition treatments tailored to explicit undertaking necessities which includes materials resolution and design specs.

Conclusion

In conclusion, mastering the complexities surrounding the twine bonding process is primary for each person in touch in semiconductors or electronics production right now. From making a choice on gorgeous parts to awareness diversified options like ball as opposed to wedge bonding—both component contributes drastically to standard product functionality and reliability. Embracing concepts while adhering to general nice practices will make certain a hit result throughout several functions.

By following this accomplished help on Understanding the Wire Bonding Process: A Comprehensive Guide you now have elementary insights into optimizing your operations at the same time as declaring prime specifications in the time of your tasks!