Understanding the Wire Bonding Process: A Comprehensive Guide

Introduction

The twine bonding procedure is a elementary process in semiconductor manufacturing and electronic assembly. It serves as a significant connection among incorporated circuits (ICs) and their substrates, enabling electric indications to drift seamlessly. With the immediate development of electronics in a lot of industries consisting of automobile, aerospace, and medical units, awareness the intricacies of twine bonding technology has not ever been more significant.

In this comprehensive information, we will be able to delve into different points of twine bonding such as its methodologies, gear, purposes, reliability tests, and future developments. By the give up of this newsletter, you can still have an intensive know-how of the twine bonding strategy and its importance in up to date electronics.

What is Wire Bonding?

Wire bonding is a means used to create electric connections among semiconductor instruments and their applications or substrates as a result of fine wires. The task customarily comes to two standard concepts: ball bonding and wedge bonding. Each formula has its own targeted packages relying on elements like materials homes and design requisites.

How Wire Bonding Works

Wire bonding employs mechanical pressure and heat to variety bonds among metallic wires—in general gold, aluminum, or copper—and pads on silicon chips or other surfaces. The alternative of materials basically depends on rate issues, thermal conductivity, and efficiency wedge wire bonding standards.

Understanding the Wire Bonding Process: A Comprehensive Guide

The Importance of Wire Bonding Technology

Wire bonding technologies plays a pivotal position in making sure legitimate connections inside of electronic units. As technologies advances against miniaturization and extended complexity, potent twine bonding ideas are vital for prime-efficiency applications.

Different Types of Wire Bonding Techniques

- This technique comprises growing a small ball on the finish of a cord by melting it with heat before making contact with the bond pad.

- Wedge bonding utilizes a flat device to press the wire towards the substrate without heating it.

- Ribbon bonding employs broader strips of metal in place of traditional spherical wires for more suitable surface field contact.

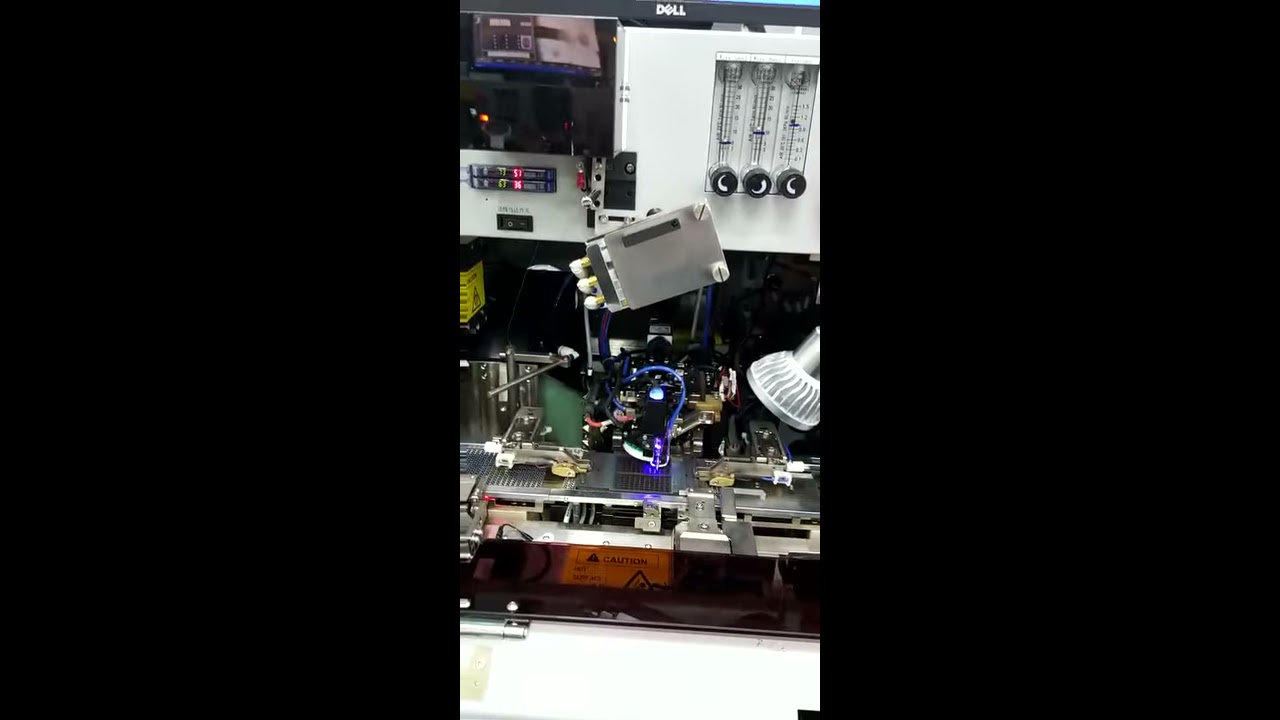

Wire Bonding Equipment: Key Components

- Wire Bonding Machine: The center of the operation where automation takes vicinity.

- Bonding Capillary Tool: Essential for positioning the wire wisely.

- Ultrasonic Generator: Supplies ultrasonic vigor during certain varieties of bonds.

Wire Bonding Applications Across Industries

Wire bonding finds use in a range of sectors:

- Automotive Electronics: Ensures official connections in defense platforms.

- Medical Devices: High reliability is paramount for life-saving device.

- Aerospace: Components should stand up to intense prerequisites.

- Consumer Electronics: Mobile units require compact preparations.

Wire Bonding Failure Analysis

Understanding possible failure modes is very important for improving reliability:

Common Failures in Wire Bonding

Failures can happen thru bond lifting or heel cracks that compromise connectivity. Identifying these problems early can save you critical losses down the line.

Wire Bonding Reliability Factors

Reliability is influenced by means of a number of motives:

- Environmental controls

- Material choices

- Bond power calibration

Quality Control in Wire Bonding

Implementing stringent high-quality handle measures guarantees that both bond meets business standards. Techniques like visual inspection or automated bond inspection play critical roles here.

Cost Implications of Wire Bonding Processes

Understanding twine bonding bills can guide agencies make proficient judgements on manufacturing:

- Material rates (gold vs aluminum)

- Labor charges linked to manual versus automatic processes

- Maintenance expenditures for machinery

Comparative Analysis: Gold vs Aluminum Wire Bonding

| Factor | Gold Wire | Aluminum Wire | |---------------------|---------------------------|-----------------------------| | Cost | Higher | Lower | | Oxidation Resistance | Excellent | Moderate | | Thermal Conductivity | Superior | Good |

Best Practices in Wire Bond Design

Proper design rules can boost reliability:

Bond Strength Considerations

Achieving most suitable bond electricity requires careful calibration of parameters including pressure settings right through software.

Specialized Techniques in Wire Bonding

Advanced systems incorporate:

These equipment cater to designated demanding situations posed via prime-density designs.

FAQs about Wire Bonding

What components are more commonly used in twine bonding?

Common elements comprise gold, aluminum, copper, and silver thanks to their awesome conductive houses.

How does environmental keep an eye on have effects on wire bonding?

Proper environmental controls mitigate disadvantages which includes oxidation or contamination that can bring about screw ups.

What industries improvement from wire bonding?

Industries like car, medical devices, aerospace, consumer electronics, and telecommunications all have faith in nontoxic cord bonds for functionality.

How do you perform good quality control exams all the way through twine bonding?

Quality checks would contain visible inspections, automatic checking out machines for bond integrity exams (shear exams), and x-ray inspections to locate hidden mistakes.

What is ribbon bonding? How does it vary from conventional techniques?

Ribbon bonding makes use of wider strips as opposed to spherical wires enabling more advantageous floor enviornment touch which enhances reliability however may also require really good methods.

Can I customize my wire bonding services?

Yes! Many suppliers provide customized options adapted to detailed task specifications consisting of fabric range and layout specifications.

Conclusion

In conclusion, getting to know the complexities surrounding the cord bonding activity is vital for all of us involved in semiconductors or electronics manufacturing today. From determining appropriate supplies to knowing totally different options like ball as opposed to wedge bonding—every factor contributes vastly to general product functionality and reliability. Embracing recommendations at the same time as adhering to verified leading practices will determine a success outcome throughout diverse programs.

By following this complete guide on Understanding the Wire Bonding Process: A Comprehensive Guide you currently have crucial insights into optimizing your operations at the same time as keeping up prime principles all the way through your tasks!