Insulated Wire Bonding: Enhancing Performance and Durability

Introduction

In the briskly evolving panorama of electronics manufacturing, the magnitude of official interconnections can't be overstated. One such technique that has received traction in latest years is insulated cord bonding. This article delves into the tricky global of wire bonding, exploring its processes, technology, tactics, and applications while emphasizing how insulated wire bonding enhances efficiency and durability.

What is Insulated Wire Bonding?

Insulated twine bonding contains the use of insulation components on bonding wires to enhance electric functionality at the same time as minimizing negative aspects corresponding to brief circuits and go-communicate. This methodology is tremendously a good suggestion in top-density packaging functions in which space is at a top class. By offering a further layer of policy cover, insulated cord bonding guarantees that digital units are usually not most effective helpful yet also lengthy-lasting.

Understanding the Wire Bonding Process

The wire bonding process comprises numerous significant steps:

Types of Insulation Materials Used

The decision of insulation fabric plays a pivotal position in choosing the effectiveness of insulated wire bonding. Common materials embody polyimide videos, silicone rubbers, and epoxy resins. Each subject matter deals distinct properties which includes thermal stability and chemical resistance.

The Importance of Wire Bonding Technology

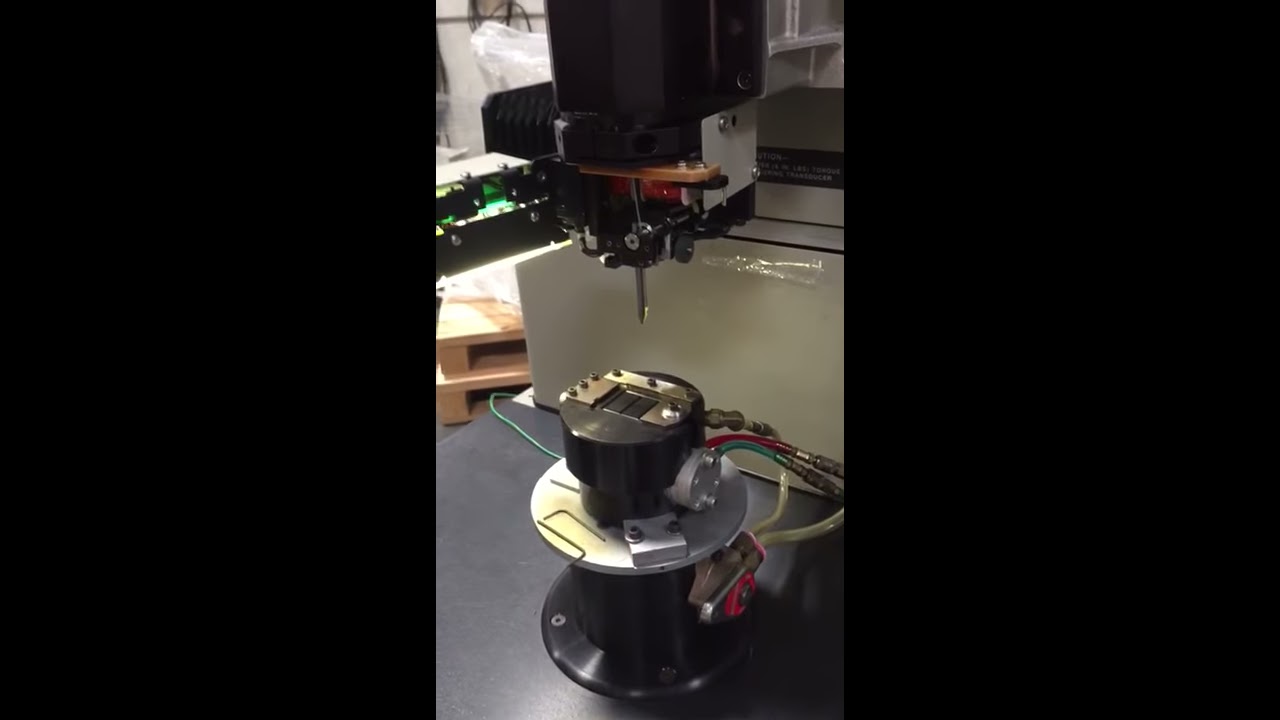

Advancements in Wire Bonding Equipment

The evolution of wire bonding technology has led to the progression of refined machines able to executing intricate tactics successfully. Modern cord bonding machines combine automation services that optimize creation cycles although holding high precision.

Benefits of Automated Wire Bonding Machines

Automated machines improve the two pace and consistency in construction environments. With elements like programmable settings and precise-time tracking platforms, producers can attain higher yields with lowered errors costs.

Wire Bonding Techniques Explained

Ball Bonding vs Wedge Bonding

Two most important programs dominate the twine bonding landscape:

- Ball Bonding: Utilizes a small ball formed at the conclusion of a gold or aluminum wire to create a bond.

- Wedge Bonding: Employs a wedge-formed device to make connections; foremost for thicker wires or in which house constraints exist.

Both systems have their merits relying on application specifics.

Thermosonic vs Ultrasonic Bonding

These methods contain distinctive calories sources:

- Thermosonic Bonding combines heat with ultrasonic vigor for amazing bonds.

- Ultrasonic Bonding is dependent solely on ultrasonic vibrations; that's sooner yet won't furnish as strong a connection as thermosonic techniques.

Wire Bonding Applications Across Industries

Wire Bonding in Semiconductors

In semiconductor manufacturing, twine bonding establishes foremost connections among chips and substrates. Its reliability quickly affects machine performance.

Applications in Automotive Electronics

As autos turn into more reliant on electronics for operation and safety characteristics, helpful twine bonding options are necessary to verify reliability lower than harsh situations.

Medical Devices and Wire Bonding Solutions

Insulated wire bonding finds its manner into clinical instruments in which reliability can suggest life or loss of life. Whether securing sensors or connecting areas inside implants, it’s integral that those bonds face up to rigorous checking out.

Wire Bond Quality Control Measures

Ensuring tremendous bonds requires strict great handle measures all through the production procedure.

Common Testing Methods for Wire Bonds

These tests support determine practicable troubles early in production cycles earlier they strengthen into luxurious screw ups.

Wire Bond Reliability Factors

Environmental Considerations in Wire Bond Reliability

Environmental motives reminiscent of temperature fluctuations and moisture degrees seriously impact bond integrity over time.

- Implement ESD protection ideas.

- Use conformal coatings for superior sturdiness in opposition to environmental stressors.

Long-term Reliability Testing Procedures

Conduct constant lengthy-term reliability tests to ascertain that bonds can withstand operational demands over increased periods.

Challenges Faced in Insulated Wire Bonding

Despite its benefits, insulated cord bonding comes with demanding situations:

Wire Bond Failure Analysis Techniques

Understanding why bonds fail is critical for making improvements to strategies:

Costs Associated with Wire Bond Processes

Understanding quotes regarding wire bonding allows organizations allocate budgets extra properly:

| Type processes | Cost Estimate | |-----------------------------|---------------| | Manual Wire Bonder | $5K - $20K | | Semi-Automatic Bonder | $20K - $75K | | Fully Automatic Bonder | $100K+ |

Investments fluctuate greatly situated on laptop capabilities and automation stages.

Training Programs for Effective Wire Bonding

To prevent pace with business improvements:

- Implement ongoing education systems masking matters from universal principles to sophisticated suggestions.

- Encourage participation in online courses or webinars targeted on modern day traits in insulated wire bonding know-how.

Learning Resources for Engineers

For engineers seeking to master insulated cord bonding:

- Access academic substances which includes "cord bonding instructional" video clips on-line.

- Download "wire bonding PDF" archives from professional assets detailing methods and methodologies.

Case Studies Illustrating Successful Applications

Examining valuable case reviews highlights how insulated wire bonding complements performance throughout a number of sectors:

Frequently Asked Questions (FAQs)

1. What are the most important forms of insulated wires utilized in electronics?

Insulated wires recurrently encompass aluminum wires lined with layers like polyimide or silicone rubber that fortify toughness and performance below varying circumstances.

2. How does temperature affect the effectiveness of insulated cord bonds?

Temperature differences can cause enlargement or contraction that will weaken bond integrity; accordingly ensuring excellent thermal administration right through operation is considered necessary.

3. What testing programs determine first-class manipulate in bonded wires?

Quality control employs quite a few trying out tricks along with pull exams, shear checks at the side of visible inspection tactics making sure every one bond meets required requirements past deployment into last merchandise.

four. Can you clarify how environmental elements have an effect on bonded wires?

Moisture publicity may just lead corrosion whereas severe temperatures would set off fatigue; for this reason employing protecting coatings will become critical when designing assemblies subjected harsher environments!

five What industries gain most from improved insulating tactics?

Industries consisting of automotive electronics healthcare structures aerospace all leverage better insulation homes guaranteeing strong functioning over longer lifespans!

6 Are there extraordinary lessons packages accessible focusing fully upon gaining knowledge of those strategies?

Yes! There are specialized guides evolved focusing on americans aiming acquire accomplished skillsets surrounding today's systems utilized inside of this container!

Conclusion

In conclusion, insulated wire bonding represents an a must-have development within electronic manufacturing techniques in the present day! As we explored throughout the time of this comprehensive aid—it now not purely improves standard efficiency but also enormously complements sturdiness throughout various applications ranging automobile sectors clinical contraptions vitality modules alike! By leveraging rising applied sciences coupled along standard practices engineers will keep pushing boundaries creating imaginitive recommendations raising ideas fine reliability!