Exploring Ribbon Bonding Applications in Diverse Industries

Introduction

In the area of electronics and semiconductor manufacturing, cord bonding has emerged as a quintessential manner for opening electric connections among accessories. Among the a good number of ways of twine bonding, ribbon bonding sticks out by reason of its amazing blessings and flexibility across assorted industries. This article delves into the difficult landscape of ribbon bonding applications, exploring how this resourceful era is revolutionizing sectors inclusive of automotive, aerospace, medical gadgets, and more.

What is Wire Bonding?

Wire bonding is a job used to create electric connections among semiconductor devices and their packaging. It contains utilizing skinny wires to attach bond pads on an integrated circuit (IC) to external leads or other chips. The commonplace purpose of twine bonding is to ascertain secure and effectual verbal exchange within electronic contraptions.

How Wire Bonding Works

The cord bonding method broadly speaking entails a few steps:

This manner can make the most of a variety of forms of constituents inclusive of gold, aluminum, copper, and silver cord bonding strategies.

Types of Wire Bonding Techniques

- Ball Bonding: Utilizes a small ball fashioned on the stop of the wire for connections.

- Wedge Bonding: Employs a wedge-fashioned tool rather then a ball for making connections.

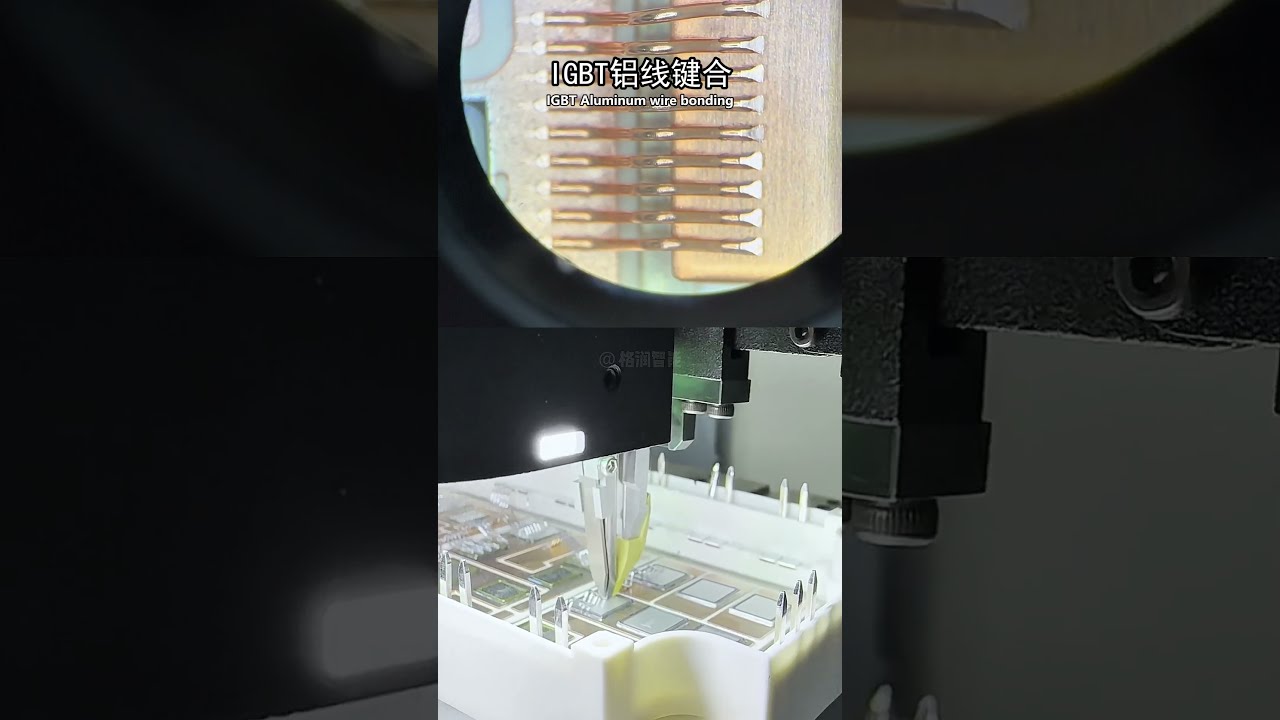

- Ribbon Bonding: Uses flat ribbons other than spherical wires to make electrical connections.

In precis, awareness those basics units the degree for diving deeper into ribbon bonding specifically.

The Ribbon Bonding Process

Ribbon bonding is a sophisticated variety of cord bonding that makes use of flat ribbons in preference to spherical wires. This technique has won traction attributable to its means to handle better existing densities and deliver decrease inductance paths in comparison to standard spherical wires.

Advantages of Ribbon Bonding

Ribbon Bonding Machine Overview

A really expert ribbon bonding equipment is priceless for executing this process adequately. These machines are designed with qualities that permit certain regulate over parameters like temperature and stress for the time of bonding.

Exploring Ribbon Bonding Applications in Diverse Industries

The versatility of ribbon bonding makes it suitable in lots of fields consisting of:

1. Automotive Electronics

In cutting-edge motors the place digital techniques are quintessential for formulation like sensors and infotainment procedures, wire bonding service ribbon bonding deals reliability beneath harsh circumstances.

Applications

- Power modules

- Sensor interfaces

2. Aerospace

Aerospace packages require lightweight yet powerful options; as a result, ribbon bonding technologies delivers environment friendly overall performance at the same time adhering to strict weight regulations.

Applications

- Satellite conversation systems

- Flight management systems

3. Medical Devices

Medical instruments necessitate reliability the place human lives are at stake; thus ribbon bonded connections ensure minimum failure charges and long-term reliability.

Applications

- Diagnostic equipment

- Implantable devices

four. Telecommunications

With prime documents costs being demanded by way of networks as we speak, ribbon bonding’s low inductance houses make it most efficient for RF modules used in telecommunications package.

Applications

- Base station transceivers

- Optical communication devices

Understanding Ribbon Wire Bonding Techniques

Gold vs Aluminum Ribbon Bonding

When deciding on material for ribbon bonding, many engineers debate between gold and aluminum ribbons:

| Feature | Gold Ribbon | Aluminum Ribbon | |-----------------------------|----------------------|-----------------------| | Cost | High | Low | | Corrosion Resistance | Excellent | Moderate | | Electrical Conductivity | Superior | Good | | Application | High-quit electronics | General-reason |

In summary, although gold ribbons present stronger conductivity and corrosion resistance, aluminum is likely to be premier wherein settlement is a problem.

Ribbon Bonding vs Wedge Bonding

Both options have their situation in manufacturing; even so, they cater to diverse desires founded on software requisites:

Comparison Table

| Feature | Ribbon Bonding | Wedge Bonding | |-----------------------------|----------------------|-----------------------| | Material | Flat ribbons | Round or flat wires | | Typical Application | High-density circuits | General IC interconnections | | Process Speed | Faster | Moderate |

While either tools can attain mighty outcomes; engineers basically pick out headquartered on categorical design constraints comparable to house boundaries or thermal properties.

Challenges in Ribbon Bonding

Despite its reward, there are demanding situations associated with ribbon bonding that want addressing:

To mitigate those demanding situations, firms as a rule spend money on guidance applications focusing on good quality manipulate measures tailored chiefly for ribbon bonding techniques.

FAQs About Ribbon Bonding

1. What industries notably use ribbon bonding?

Ribbon bonding finds functions as a rule in car electronics, aerospace manufacturing, medical contraptions creation, and telecommunications sectors resulting from its extraordinary advantages over standard systems.

2. How does ribbon size have an affect on overall performance?

Larger ribbon sizes ordinarilly let top modern capacities but may just include commerce-offs concerning mechanical flexibility or thermal dissipation characteristics; therefore cautious consideration is principal stylish on application wants.

3. Can I use any variety of cloth for ribbon bonding?

While aluminum and gold are everyday preferences as a consequence of their conductivity residences; it can be an important to evaluate compatibility together with your extraordinary program ahead of deciding upon any material classification for max consequences.

four. What motives have an effect on bond force all the way through the job?

Factors include fabric form used (gold vs aluminum), ambient working conditions (temperature/humidity), adhesion techniques hired (ultrasonic vs thermosonic), among others which all play vital roles influencing normal bond integrity put up-activity completion.

5. Are there working towards elements conceivable for gaining knowledge of approximately twine/ribbon bonding?

Yes! Numerous universities be offering lessons centered on points surrounding trendy programs like those involved with either cord & particularly inside places appropriate instantly in direction of fantastic implementation approaches round utilising this era efficiently!

6. What's subsequent for ribbon know-how inventions?

As demand keeps starting to be throughout a number of sectors witnessing developments daily—from expanded automation abilties through AI integration fostering smarter resolution-making techniques—to improved material research paving approach towards novel purposes expanding beyond typical utilizations obvious at the moment!

Conclusion

In end, exploring ribbon bonding programs famous its pivotal role throughout many different industries from automotive electronics to scientific units and past. By leveraging its specific attributes similar to excessive present means and decreased inductance pathways—engineers can force innovation when guaranteeing reliability within their designs! As we circulation forward into an generation fueled by means of faster technological developments—ribbon bonds will most likely continue to be at forefront shaping future landscapes within digital production nation-states!

This article no longer simply highlights most important aspects concerning “Exploring Ribbon Bonding Applications in Diverse Industries,” however additionally serves as an informative useful resource aimed at modifying know-how surrounding tactics fundamental towards advancing engineering practices relocating ahead!