Copper vs Silver Wire Bonding: Which is Right for You?

Introduction

In the evolving global of electronics, the decision of materials plays a pivotal position in finding out the overall performance and reliability of units. Among countless interconnection ways, cord bonding stands proud as a serious strategy used to determine electrical connections within semiconductor programs and different electronic formulation. This article delves into an in-depth comparability among copper and silver twine bonding, exploring their houses, reward, dangers, and applications. By the finish of this comprehensive booklet, you may have a clearer wisdom of which wire bonding formulation is appropriate for your exact desires.

Copper vs Silver Wire Bonding: Which is Right for You?

The debate surrounding copper vs silver twine bonding has been ongoing in the semiconductor enterprise. Each fabric gives interesting advantages and downsides, affecting the whole lot from check to overall performance.

What is Wire Bonding?

Wire bonding is a widely followed procedure used to create electric interconnections between semiconductor devices and their packaging. It consists of using tremendous wires—in most cases product of gold, aluminum, copper, or silver—to attach bond pads on incorporated circuits (ICs) to external leads or substrates.

How Wire Bonding Works

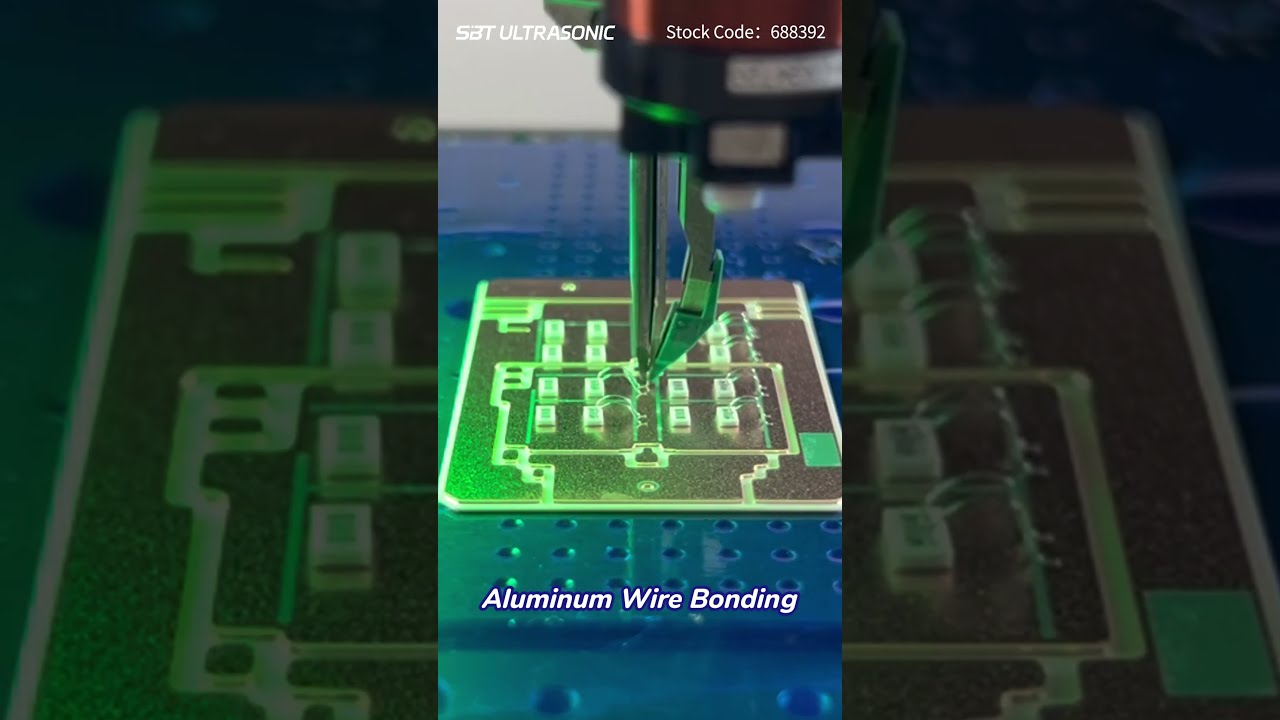

During the cord bonding job, a thin metallic wire is attached at one stop to a pad on the semiconductor die the usage of heat and stress. The other cease is then bonded to a lead body or substrate because of related concepts. The two primary types of bond techniques are thermosonic and ultrasonic bonding.

Understanding Wire Bonding Technology

Types of Wire Bonding Techniques

- Ball Bonding: This components employs an electrically heated ball-shaped tip that forms a bond between the twine and pad.

- Wedge Bonding: In this manner, a wedge-shaped software applies pressure even though ultrasonic vigor is helping create a bond.

- Ribbon Bonding: Utilizes flat ribbon wires in preference to around ones for more advantageous surface field touch.

Wire Bonding Equipment Overview

To practice twine bonding efficaciously, really expert tools equivalent to automatic twine bonders and guide setups are utilized. Each computer varies in means and application based on manufacturing volume requisites.

Copper Wire Bonding: Advantages & Applications

Properties of Copper Wire

Copper boasts magnificent electric conductivity and thermal houses, making it true for prime-functionality purposes. Its tensile power additionally lets in for high-quality pitch designs.

Advantages of Copper Wire Bonding

Applications in Electronics

- Power modules

- Automotive electronics

- Aerospace applications

Silver Wire Bonding: Advantages & Applications

Properties of Silver Wire

Silver points ultimate conductivity when put next to both copper and gold. It’s mainly Wire Bonding advantageous in high-frequency applications simply by its cut back resistivity.

Advantages of Silver Wire Bonding

Applications in Electronics

- RF modules

- High-strength applications

- LED manufacturing

Comparative Analysis: Copper vs Silver Wire Bonding

| Feature | Copper | Silver | |--------------------------|----------------------------|-----------------------------| | Cost | Lower | Higher | | Conductivity | Good | Excellent | | Corrosion Resistance | Moderate | High | | Strength | High | Moderate | | Thermal Conductivity | Good | Excellent |

Factors Influencing Your Choice Between Copper vs Silver Wire Bonding

When selecting among copper and silver twine bonding approaches, contemplate explanations like:

Wire Bond Quality Control Measures

Maintaining best at some stage in the twine bonding activity is an important for making sure software reliability:

Wire Bond Failure Analysis Techniques

Understanding capability failure modes can guide mitigate negative aspects:

- Common failure causes embody oxidation at bond web sites, infection for the period of manufacturing techniques, and fallacious bonding approaches.

- Employ non-destructive trying out systems like X-ray inspection to perceive considerations early on.

Conclusion

In conclusion, the two copper and silver wire bonding concepts have their very own merits and limitations depending on special specifications concerning settlement, overall performance, atmosphere, and application sort. Evaluating these causes carefully will aid check which procedure appropriate fits your necessities—no matter if you lean closer to value-productive copper ideas or decide upon prime-efficiency silver alternate options.

Frequently Asked Questions (FAQs)

- The normal adjustments lie in rate-effectiveness (copper being less expensive), conductivity (silver being most advantageous), corrosion resistance (silver has enhanced resistance), and mechanical properties (copper ordinarily bargains better tensile power).

- Industries like car electronics, aerospace purposes, LED production, RF communications, vigor modules production utilize quite a number kinds of cord bonding technological know-how substantially.

- Factors consisting of utility ambiance prerequisites (temperature variations), preferred electrical homes (conductivity standards), budget constraints (expense considerations), and creation quantity may want to assist your resolution-making method regarding which technique is incredible.

- Common mess ups come with incomplete bonds on account of inadequate power or vigor applied throughout the time of processing; oxide formations at bond surfaces most well known to susceptible connections; illness for the duration of assembly impacting adhesion satisfactory; between others.

- Transitioning from one subject matter (like gold) towards one more possibility calls for cautious attention regarding compatibility with latest approaches/tactics whereas assessing overall performance impacts that will rise up from ameliorations made throughout manufacturing runs.

6. What materials can aid in addition my knowledge about complex facets linked exceptionally closer to different forms/varieties located inside this area?

- For the ones keen freshmen seeking deeper insights into precise methodologies used inside of this discipline may perhaps find value attending webinars hosted via trade authorities along academic lookup papers attainable on-line focusing particularly upon subject matters linked right now with a lot of sub-disciplines crucial toward state-of-the-art-day electronics design/manufacturing practices.*

This comprehensive article serves as an extensive aid on "Copper vs Silver Wire Bonding" whereas addressing useful matters valuable across several technical dimensions!