Choosing the Right Wire Bonding Method for Your Needs

Introduction

In the area of electronics and semiconductor manufacturing, the wire bonding process serves as a crucial link among system, ensuring that they converse quite simply. As expertise keeps to evolve, know-how how to settle upon the right wire bonding manner will become a must-have no longer only for engineers but for each person fascinated in electronics creation.

This article objectives to deliver an exhaustive evaluate of various twine bonding technologies, options, and apparatus accessible lately. By diving deep into matters ranging from gold vs. aluminum cord bonding to twine bonding reliability, we will publication you via the complexities of selecting wire bonding process the most useful formula tailor-made in your distinctive wants.

What is Wire Bonding?

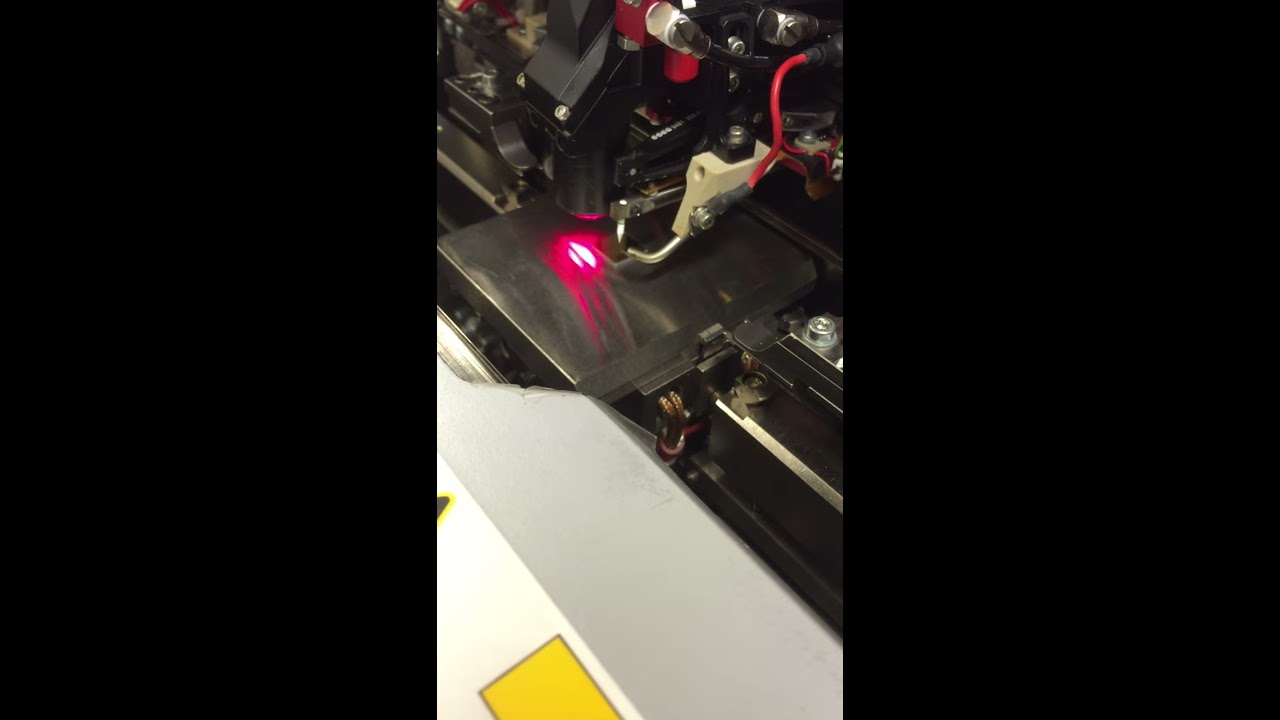

Wire bonding is a method used to create interconnections between semiconductor instruments like incorporated circuits (ICs) and their packaging. Essentially, it establishes electric connections driving nice wires crafted from gold, aluminum, copper, or different metals. The cord bonding approach is critical for guaranteeing reliable performance in electronic contraptions.

The Importance of Wire Bonding in Electronics

Wire bonding plays a pivotal function in modern day electronics by way of:

- Facilitating connections in IC packaging

- Connecting chips in multi-chip modules

- Enabling conversation between totally different digital components

Without effectual cord bonding techniques and methodologies, many technological improvements we enjoy as of late might be implausible.

Wire Bonding Process Overview

Understanding how cord bonding works is major earlier than diving into exceptional tactics. The procedure as a rule comes to 3 main steps:

Types of Wire Bonding Techniques

There are numerous kinds of twine bonding procedures, each one with its certain applications:

- Ball Bonding: Often appreciated for its simplicity and effectiveness.

- Wedge Bonding: Ideal for excessive-speed packages.

- Ribbon Bonding: Suitable for thicker wires utilized in vigor modules.

These thoughts can range radically based totally on points along with subject material kind (gold vs aluminum), bond potential requisites, and environmental situations.

Choosing the Right Wire Bonding Method for Your Needs

Selecting the acceptable wire bonding approach hinges on various factors which include value issues, substances used, favored bond reliability, and application specifics.

Factors Influencing Your Choice

- Gold cord bonding excels in low-tension environments even though aluminum supplies value-fine answers.

- For quintessential packages like automotive electronics or aerospace system, strong bonds are non-negotiable.

- High-amount manufacturing can even necessitate computerized machines able to speedy-paced operations.

Cost Implications

Cost can noticeably result your alternative of cord bonding strategies. Ball and wedge bonder machines can fluctuate drastically in value stylish on functions like automation level and precision talents.

Table 1: Cost Comparison of Different Methods

| Method | Initial Cost | Operating Cost | Typical Applications | |----------------|--------------|----------------|------------------------------------------------| | Ball Bonding | Moderate | Medium | Microelectronics | | Wedge Bonding | High | Low | Automotive & Aerospace Electronics | | Ribbon Bonding | High | Medium | Power Modules |

Understanding Different Types of Wire Bonding

Gold Wire Bonding

Gold twine bonding remains probably the most such a lot prevalent methods as a consequence of its desirable conductivity and resistance to oxidation. It’s in most cases utilized in high-frequency applications because it provides optimum overall performance qualities.

Advantages:

- Exceptional conductivity

- Corrosion resistance

Disadvantages:

- Higher materials fees in contrast to aluminum

Aluminum Wire Bonding

For price-touchy tasks requiring good efficiency with no breaking the bank, aluminum cord bonding is regularly desired.

Advantages:

- Lower textile costs

- Good mechanical properties

Disadvantages:

- Less conductive than gold

- Susceptible to oxidation except wisely treated

Copper Wire Bonding

Copper has emerged as a good option owing to its magnificent conductivity and slash value relative to gold.

Advantages:

- Low-money material

- Excellent thermal properties

Disadvantages:

- Requires careful managing due to oxidation issues

Wire Bond Quality Control Measures

Quality keep an eye on during the wire bonding approach is very important for guaranteeing long-time period reliability of digital merchandise.

Common Inspection Techniques

Table 2: Types of Inspection Techniques

| Technique | Description | |-----------------------------|------------------------------------------| | Visual Inspection | Manual examine for surface defects | | X-Ray Inspection | Non-detrimental internal inspection | | Pull Test | Measures bond force |

FAQ Section

1. What is the surest cloth for twine bonding?

Gold offers correct conductivity yet comes at a top class check; aluminum serves as a more low-cost selection with ample overall performance for lots applications.

2. How do I want among ball bond vs wedge bond?

Consider your program's speed standards; ball bonds are in most cases more easy yet wedges provide superior efficiency at excessive speeds.

3. What are well-liked mess ups for the period of cord bonding?

Common failure modes incorporate bond lifting, heel cracks, and infection for the period of processing which will degrade pleasant over the years.

four. How does environmental keep watch over affect wire bonding?

Environmental aspects corresponding to humidity can impression adhesion; controlling temperature and moisture stages ensures most beneficial situations for efficient bonds.

5. Are there any education materials purchasable?

Yes! Various on-line programs be offering comprehensive tutorials on unique features of twine bonding which include useful demonstrations through video content material or downloadable PDFs.

6. What industries in most cases make the most of wire bonding?

Industries including automotive electronics, aerospace engineering, clinical gadgets manufacture, LED creation make use of those procedures seriously through their reliability specifications.

Conclusion

Choosing the right cord bonding formulation to your needs calls for careful consideration of various factors adding fabric charges, manufacturing volume, required bond power, and different application calls for. Understanding the ins-and-outs—from sorts like ball or wedge bonds to good quality control measures—will situation you neatly within this tricky container of generation.

As call for continues to develop throughout sectors inclusive of automotive electronics or aerospace era in which stable connections are paramount—staying abreast with developments like ribbon wiring recommendations will retain you competitive! Whether you are an engineer looking to refine your talent due to specialised classes or conveniently wish insight into trade traits—the pursuit does not conclusion right here; it can be ever-evolving!

By making knowledgeable choices regarding programs and equipment tailored peculiarly towards mission standards—agencies can develop effectivity whilst reducing ordinary operational quotes—all at the same time as paving inventive pathways ahead within today's dynamic marketplace!