Choosing a Ribbon Bonding Machine: Key Considerations

Introduction to Ribbon Bonding

In the sector of semiconductor production and electronic assembly, the cord bonding course of plays a pivotal function. Among the quite a few systems handy, ribbon bonding has emerged as a noticeably beneficial components for creating trustworthy electric connections in integrated circuits (ICs) and energy modules. This article delves into Choosing a Ribbon Bonding Machine: Key Considerations, imparting insights into what makes a good ribbon bonding laptop, its functions, and points influencing your decision.

Understanding the Wire Bonding Process

Before we dive into ribbon bonding particularly, it is vital to appreciate the wider context of twine bonding. The cord bonding system consists of connecting semiconductor gadgets or formula applying high quality wires created from elements along with gold, aluminum, copper, or silver. These connections are indispensable for ensuring electric alerts can journey between distinct components of an digital tool.

Types of Wire Bonding Techniques

There are numerous twine bonding systems used in electronics:

-

Ball Bonding: Involves forming a ball at the finish of a twine the use of heat and ultrasonic electricity previously making contact with the bond pad.

-

Wedge Bonding: Utilizes a wedge-formed device to create bonds by means of utilizing stress as opposed to warmth.

-

Ribbon Bonding: Employs flat ribbons in preference to around wires, which could be superb for specific programs like continual modules.

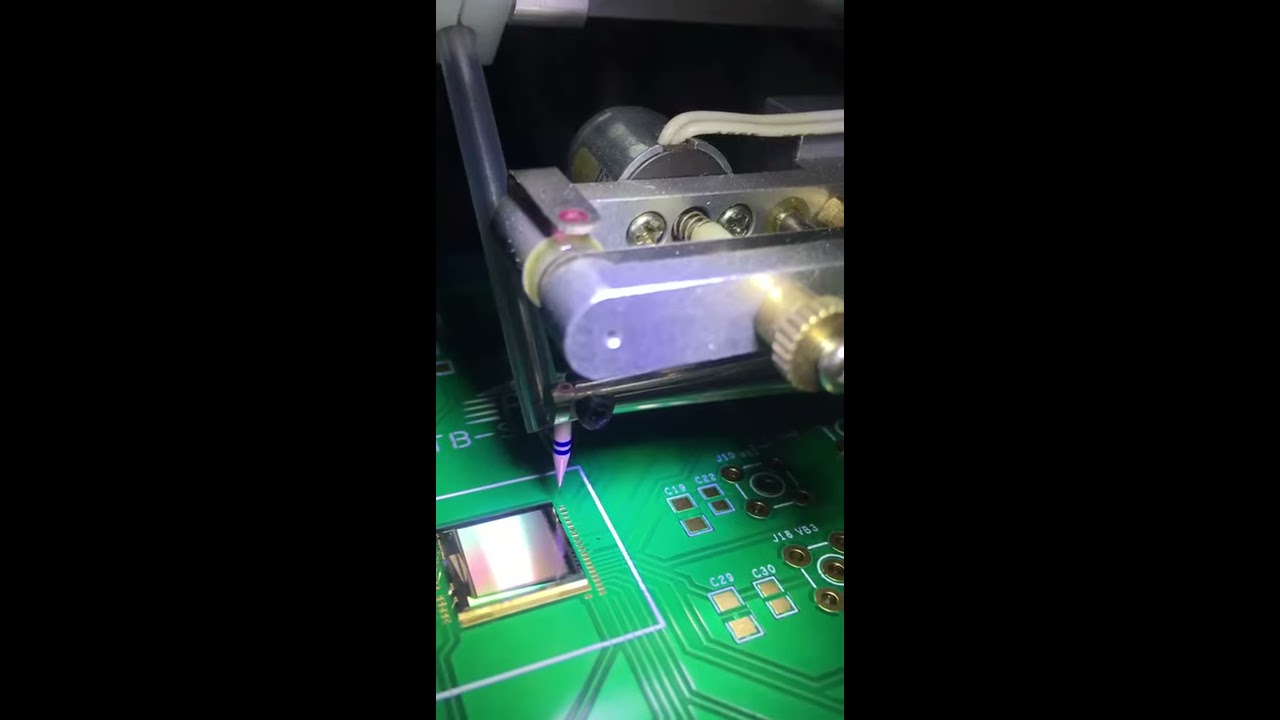

What is Ribbon Bonding?

Ribbon bonding is a specialised model of wire bonding where flat, rectangular ribbons are used instead of standard spherical wires. This methodology lets in for more suitable bond part and might lead to more suitable thermal overall performance and reduced inductance – severe components in excessive-frequency purposes.

Applications of Ribbon Bonding

Ribbon bonding is really lucrative in:

-

Power Modules: Where prime existing carrying skill is vital.

-

LED Manufacturing: For productive thermal control.

-

Automotive Electronics: Where reliability and durability are paramount.

Choosing a Ribbon Bonding Machine: Key Considerations

When it involves making a choice on a ribbon bonding device, there are a lot aspects you need to be aware to make sure you make an suggested choice that fits your creation wishes.

1. Types of Ribbon Bonding Machines

There are more often than not two styles of ribbon bonding machines:

-

Manual Ribbon Bonders: Require an operator's intervention for every bond however offer flexibility in low-amount scenarios.

-

Automatic Ribbon Bonders: Designed for prime-extent production with automated tactics guaranteeing consistency and efficiency.

2. Size and Configuration

The measurement of the ribbon bonding computer concerns. You needs to review your workspace and suppose whether you require compact types for small places or better setups for tremendous operations.

Machine Configuration Options

- Horizontal vs. Vertical Configuration

- Single vs. Multi-head Machines

three. Material Compatibility

Different ribbon bonding machines help quite a lot of supplies—gold, aluminum, or copper ribbons. Ensure that your chosen tools can cope with the certain supplies you intend to apply depending to your application requisites.

four. Speed and Throughput Capacity

The pace at which bonds is usually made promptly affects productivity degrees. Evaluate how many bonds in keeping with hour the mechanical device can supply in comparison on your production ambitions.

five. Customization Options

Certain brands be offering customizable machines tailor-made to specified demands which include various bond sizes or techniques used (i.e., thermosonic vs. ultrasonic).

6. User Interface and Control Systems

A user-pleasant interface complements operational performance through lowering classes time for employees worried in working the machinery.

7. Maintenance Requirements

Understanding preservation workouts facilitates steer clear of sudden downtimes which may hinder creation schedules.

8. Cost Implications

Budget constraints may also prohibit your choices; but, it's fundamental no longer basically to trust initial purchase expenditures yet additionally lengthy-term operational rates (which include preservation).

Frequently Asked Questions (FAQs)

FAQ 1: What is the accepted gain of the usage of ribbon bonding over average wire bonding?

Ribbon bonding bargains bigger surface region contacts that reinforce thermal functionality and reduce inductance—making it terrific for prime-frequency functions.

FAQ 2: How does one examine which material is perfect proper for their cord bonds?

The determination repeatedly relies on points like price-effectiveness, environmental conditions (corrosion), mechanical stresses, and electric conductivity standards vital to the application handy.

FAQ 3: Can ribbon bonders be used for microelectronics?

Yes! Ribbon bonders have been properly hired in microelectronics the place smaller sizes bring about magnificent overall performance upgrades when holding reliability requisites.

FAQ 4: Are automated ribbon bonders extra luxurious than handbook ones?

Yes, computerized methods extensively come at bigger rates as a consequence of their complex era functions; youngsters, they routinely repay thru extended productiveness over the years.

FAQ 5: How does one make sure consistent high quality keep watch over all over ribbon bonding?

Implementing rigorous inspection protocols similar to visible inspections or automated testing equipment guarantees that any defects coming up during construction might possibly be right away identified and rectified beforehand they affect closing merchandise adversely.

FAQ 6: What variety of lessons is needed for running those machines without problems?

Operators must always obtain comprehensive working towards covering each theoretical features—such as realizing extraordinary different types of bonds—and reasonable advantage involving mechanical device operation itself along with troubleshooting programs if themes get up for the duration of processing tiers!

Conclusion

Selecting the desirable ribbon bonding laptop requires cautious attention across distinctive dimensions—from information the technical points in touch in lots of different types of bonds using comparing doable rates linked to possession over the years! By that specialize in key concerns including drapery compatibility alongside user interface alternatives even as holding long term renovation exercises in mind—you’ll situation yourself favorably inside this competitive landscape! Investing properly immediately will yield large returns the next day to come permitting seamless integration into ever-evolving technological improvements seen across industries everywhere along with aerospace strength electronics amtech Processes clinical devices car sectors amongst others!

In summary, this support on "Choosing a Ribbon Bonding Machine: Key Considerations" goals no longer in basic terms at presenting insights that drive advised judgements however additionally emphasizes asserting extraordinary ideas all through any given production activity!