Choosing a Ribbon Bonding Machine: Key Considerations

Introduction to Ribbon Bonding

In the sector of semiconductor production and electronic meeting, the cord bonding system plays a pivotal role. Among the varied strategies accessible, ribbon bonding has emerged as a extraordinarily beneficial procedure for developing professional electric connections in integrated circuits (ICs) and vigour modules. This article delves into Choosing a Ribbon Bonding Machine: Key Considerations, offering insights into what makes an incredible ribbon bonding machine, its packages, and motives influencing your alternative.

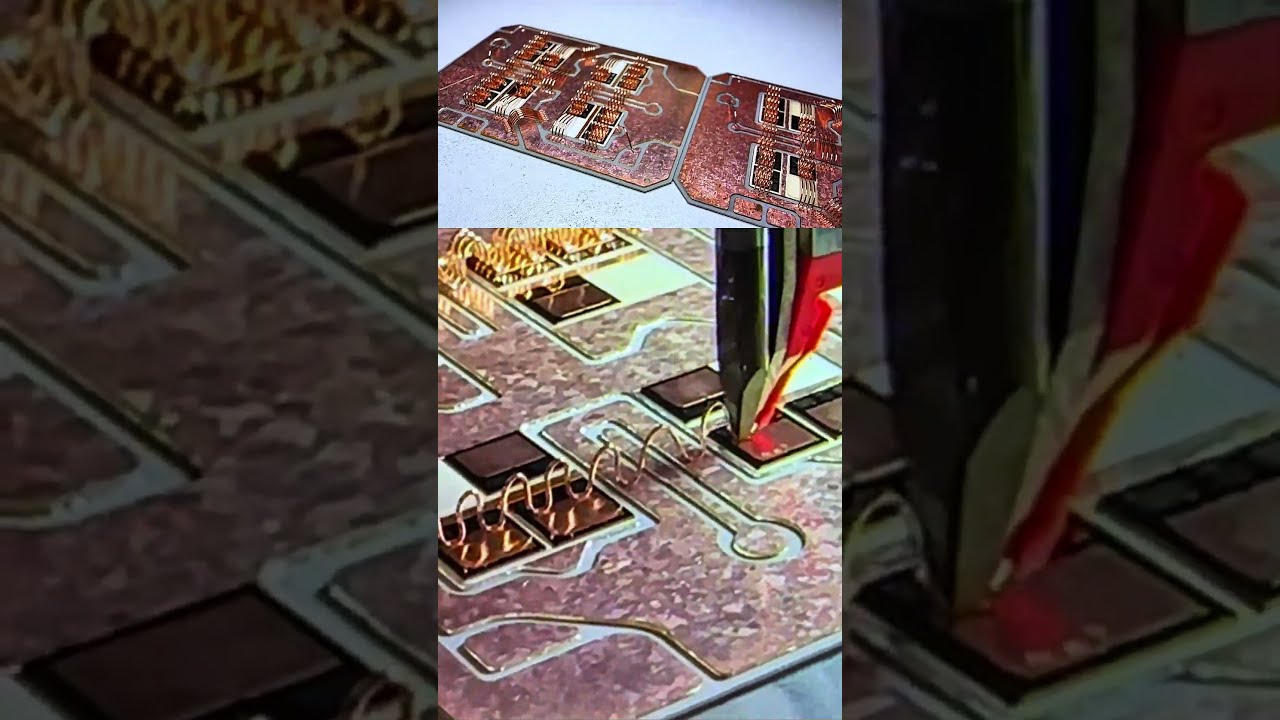

Understanding the Wire Bonding Process

Before we dive into ribbon bonding especially, this is critical to have an understanding of the broader context of wire bonding. The cord bonding manner consists of connecting semiconductor devices or resources riding wonderful wires product of ingredients akin to gold, aluminum, copper, or silver. These connections are simple for making certain electric indications can travel among totally different materials of an digital instrument.

Types of Wire Bonding Techniques

There are a number of wire bonding tactics used in electronics:

-

Ball Bonding: Involves forming a ball on the finish of a wire by means of warmness and ultrasonic vigor in the past making touch with the bond pad.

-

Wedge Bonding: Utilizes a wedge-formed tool to create bonds by means of making use of rigidity in preference to warm.

-

Ribbon Bonding: Employs flat ribbons as opposed to circular wires, which will likely be helpful for particular programs like vigor modules.

What is Ribbon Bonding?

Ribbon bonding is a really good kind of twine bonding the place flat, square ribbons are used rather than typical around wires. This process enables for more beneficial bond field and will lead to more desirable thermal overall performance and diminished inductance – primary elements in high-frequency packages.

Applications of Ribbon Bonding

Ribbon bonding is extremely really helpful in:

-

Power Modules: Where excessive latest carrying capacity is fundamental.

-

LED Manufacturing: For efficient thermal administration.

-

Automotive Electronics: Where reliability and longevity are paramount.

Choosing a Ribbon Bonding Machine: Key Considerations

When it involves identifying a ribbon bonding machine, there are a number of motives you want to evaluate to ascertain you make an suggested selection that fits your production wishes.

1. Types of Ribbon Bonding Machines

There are in the main two forms of ribbon bonding machines:

-

Manual Ribbon Bonders: Require an operator's intervention for each bond yet be offering flexibility in low-volume eventualities.

-

Automatic Ribbon Bonders: Designed for excessive-amount creation with computerized processes guaranteeing consistency and performance.

2. Size and Configuration

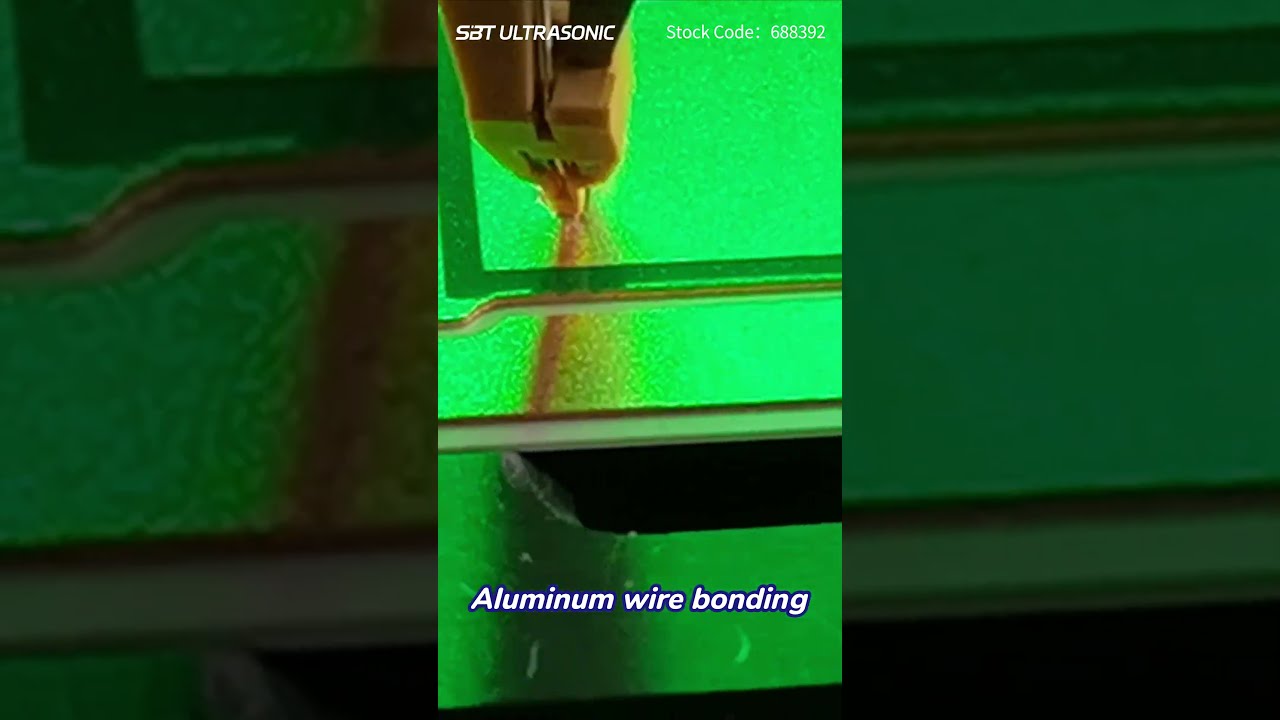

The dimension of the ribbon bonding computer topics. You need to consider your workspace and examine regardless of whether you require compact types for small places or aluminum wire bonding large setups for sizeable operations.

Machine Configuration Options

- Horizontal vs. Vertical Configuration

- Single vs. Multi-head Machines

3. Material Compatibility

Different ribbon bonding machines support varied materials—gold, aluminum, or copper ribbons. Ensure that your preferred system can maintain the distinctive resources you intend to make use of primarily based to your program requisites.

4. Speed and Throughput Capacity

The velocity at which bonds can be made in an instant affects productiveness phases. Evaluate what percentage bonds in step with hour the device can give in comparison in your creation aims.

five. Customization Options

Certain brands provide customizable machines adapted to certain needs corresponding to varying bond sizes or recommendations used (i.e., thermosonic vs. ultrasonic).

6. User Interface and Control Systems

A user-pleasant interface complements operational efficiency by cutting back tuition time for body of workers worried in running the machinery.

7. Maintenance Requirements

Understanding upkeep workouts supports evade unfamiliar downtimes that could preclude creation schedules.

8. Cost Implications

Budget constraints may additionally limit your options; besides the fact that children, it really is valuable not simply to evaluate initial acquire charges however additionally lengthy-time period operational expenditures (along with repairs).

Frequently Asked Questions (FAQs)

FAQ 1: What is the principal talents of applying ribbon bonding over natural cord bonding?

Ribbon bonding affords bigger floor domain contacts that get better thermal overall performance and decrease inductance—making it choicest for high-frequency functions.

FAQ 2: How does one establish which textile is most beneficial acceptable for their cord bonds?

The possibility as a rule relies upon on elements like payment-effectiveness, environmental conditions (corrosion), mechanical stresses, and electrical conductivity requirements suitable to the utility to hand.

FAQ 3: Can ribbon bonders be used for microelectronics?

Yes! Ribbon bonders have been with ease employed in microelectronics where smaller sizes cause outstanding performance advancements while keeping reliability specifications.

FAQ 4: Are computerized ribbon bonders more dear than manual ones?

Yes, automated techniques largely come at bigger costs caused by their stepped forward era skills; notwithstanding, they on the whole repay with the aid of larger productivity over the years.

FAQ five: How does one be sure constant first-rate control throughout the time of ribbon bonding?

Implementing rigorous inspection protocols together with visible inspections or automated checking out procedures guarantees that any defects developing for the duration of construction is additionally quickly diagnosed and rectified beforehand they effect ultimate products adversely.

FAQ 6: What reasonably training is required for working these machines quite simply?

Operators needs to take delivery of complete instructions protecting the two theoretical aspects—reminiscent of realizing distinctive kinds of bonds—and life like potential associated with system operation itself along side troubleshooting options if problems rise up all through processing stages!

Conclusion

Selecting the exact ribbon bonding computer requires cautious attention across numerous dimensions—from wisdom the technical aspects in touch in a considerable number of forms of bonds as a result of evaluating talents bills related to ownership over the years! By that specialize in key considerations akin to drapery compatibility alongside person interface alternatives although maintaining future protection routines in brain—you’ll position your self favorably inside of this aggressive landscape! Investing properly in these days will yield substantive returns tomorrow permitting seamless integration into ever-evolving technological developments observed across industries around the globe which include aerospace electricity electronics medical devices car sectors amongst others!

In abstract, this marketing consultant on "Choosing a Ribbon Bonding Machine: Key Considerations" goals now not simply at imparting insights that drive advised selections yet also emphasizes keeping notable standards in the course of any given manufacturing procedure!