A Deep Dive into Wire Bonding Machines and Equipment

Introduction

In the quick-paced global of electronics production, the significance of nice interconnection concepts should not be overstated. Among those, cord bonding emerges as a cornerstone expertise. This article objectives to offer a comprehensive research of wire bonding machines and equipment, delving into quite a lot of components along with tactics, technology, thoughts, packages, and long term traits in the marketplace. Understanding cord bonding is main for engineers and brands alike in attaining reliability and first-class in digital contraptions.

What is Wire Bonding?

Wire bonding is a way used to create electric connections among semiconductor chips and their packages or substrates. It comprises the usage of fine wires—pretty much made up of gold, aluminum, copper, or silver—to establish those connections. The system shall be conducted the use of varied concepts corresponding to ball bonding, wedge bonding, and ribbon bonding.

The Wire Bonding Process

The cord bonding method usually involves countless key steps:

This difficult technique guarantees solid connections that are significant for the performance of electronic contraptions.

Types of Wire Bonding Techniques

Wire bonding generation has developed through the years, ensuing in distinctive concepts perfect for alternative applications:

Ball Bonding

Ball bonding is one of the most most widely used programs, notably the use of gold or copper wires. In this approach:

- A ball is fashioned at the cease of the twine utilising warmth.

- The ball is then pressed onto the bond pad to model a connection.

Wedge Bonding

Wedge bonding employs a flat software as opposed to a ball to make touch with each surfaces. This procedure is chiefly worthy for:

- Aluminum wires

- Applications requiring cut temperatures

Ribbon Bonding

Ribbon bonding makes use of flat ribbons in preference to around wires, taking into consideration top existing capacities and reduced inductance. It's most likely utilized in vitality modules and Helpful resources prime-frequency packages.

Wire Bonding Machines: An Overview

What Are Wire Bonding Machines?

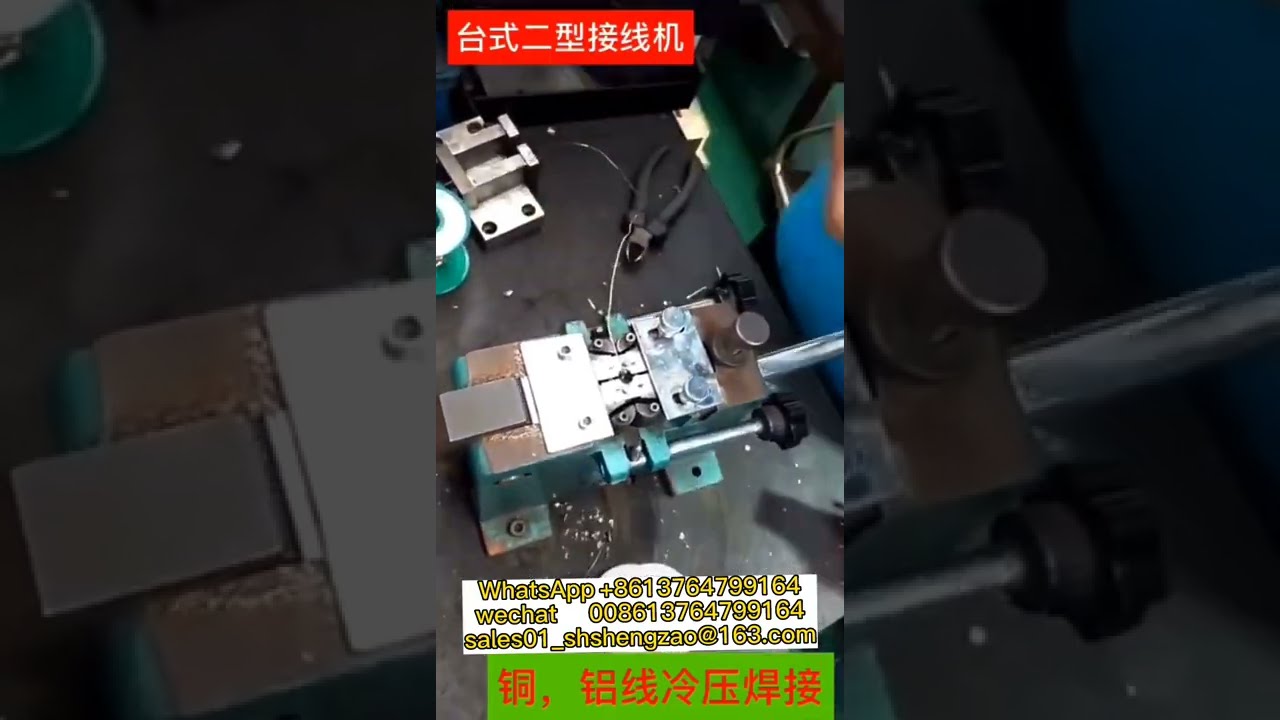

Wire bonding machines are specialized gear designed to automate the twine bonding manner. They come in a range of bureaucracy together with guide, semi-computerized, and thoroughly automatic machines.

Features of Modern Wire Bonding Equipment

Modern wire bonding strategies be offering a large number of facets aimed at rising performance and making certain awesome bonds:

- Programmable settings

- Advanced monitoring systems

- Automated inspection tools

These qualities assistance streamline manufacturing at the same time as conserving stringent high-quality manipulate ideas.

How Wire Bonding Works: A Technical Insight

Understanding how twine bonding works includes grasping equally mechanical and thermal facets:

Bond Strength in Wire Bonding

Bond capability is indispensable for reliability in digital gadgets; it is going to be stimulated through points which include:

- Material determination (gold vs aluminum)

- Environmental conditions

- Process parameters (temperature and power)

Measuring bond energy most commonly involves pull tests or shear tests designed to assess the integrity of connections.

Wire Bonding Applications Across Industries

Wire bonding reveals its utility throughout various sectors via its adaptability:

1. Wire Bonding in Semiconductors

The semiconductor industry is predicated seriously on twine bonding for connecting built-in circuits (ICs) to packages or substrates with ease.

2. Wire Bonding for Medical Devices

Medical instruments require high-reliability connections; to that end many make use of developed cord bonding recommendations like satisfactory pitch ball bonding.

3. Automotive Electronics Wire Bonding

As vehicles changed into extra sophisticated with electronics, dependableremember interconnections by using wire bonds are necessary for security approaches and infotainment positive aspects.

The Economics of Wire Bonding: Cost Considerations

Understanding the price implications linked to one of a kind twine bonding strategies can lend a hand producers optimize their operations:

1. Initial Investment vs Long-term Costs

While automatic machines have a larger prematurely value, they oftentimes set off cut back hard work expenses through the years resulting from increased throughput.

2. Material Costs: Gold vs Aluminum vs Copper Wires

Gold wires are more dear than aluminum however present awesome efficiency less than distinct conditions (e.g., top-frequency purposes).

Quality Control in Wire Bonding Processes

Ensuring caliber in the time of manufacturing tactics can stay away from defects that lead to failure modes later on:

1. Visual Inspection Techniques

Visual inspection stays among the maximum straight forward processes for picking abilities trouble early on equivalent to bond elevate-off or heel cracks.

2. Non-unfavorable Testing Methods

Techniques comparable to x-ray inspection or automatic optical inspection (AOI) enable manufacturers to assess bond integrity with out unfavorable substances.

Wire Bond Failure Analysis: Understanding Defects

Fail-dependable layout calls for understanding how failures arise inside of bonded buildings:

Common Types of Wire Bond Failures

| Failure Mode | Description | |---------------------|-----------------------------------------------| | Heel Cracks | Cracks at the base of the bond | | Lift-Off | Complete detachment from bond pad | | Oxidation | Deterioration by using environmental publicity |

Understanding these failure modes enables inform higher layout practices and preservation schedules.

FAQs

1. What components are characteristically used for wire bonds?

Gold, aluminum, copper, and silver are established parts used for cord bonds as a result of their conductive residences.

2. How does temperature influence the twine bonding activity?

Temperature performs a giant position; upper temperatures can increase bond strength yet may end in fabric degradation if now not managed right.

3. What industries predominantly use twine bonding technological know-how?

Industries encompass semiconductors, automobile electronics, medical units, aerospace engineering, telecommunications, and many others.

4. How can I be told greater approximately twine bonding tactics?

Numerous elements exist on-line consisting of tutorials purchasable in PDF format or academic videos that present visual demonstrations of strategies in contact in twine binding.

5. What are a few popular demanding situations confronted for the period of wiring tactics?

Challenges incorporate coping with thermal enlargement adjustments between ingredients used or combating oxidation earlier making connections that could compromise integrity.

Conclusion

In conclusion, working out "A Deep Dive into Wire Bonding Machines and Equipment" famous its principal position across assorted industries—from semiconductors to automotive electronics—where dependable interconnections model the backbone of present day know-how building efforts right this moment! By getting to know each common techniques like ball/wedge/ribbon processes together with new inventions emerging from developments inside Industry four.0 frameworks—brands stand poised not just in simple terms live on yet thrive amidst ever-increasing rivalry landscape beforehand!

With understanding won all the way through this exploration—no matter if you might be an engineer searching for real looking insights into implementing valuable thoughts within your own operations—or absolutely curious approximately modern day trends shaping long term landscapes—remember that thorough comprehension leads in the long run in opposition t improved productivity & achievement within any field involving problematic electronic methods!