Wooden Jack Plane Sketch Code,Inexpensive Pontoon Boats 30,17 Bass Boat Trailer Zone,Boat Sailing Workshop Zone - Try Out

admin

admin

Skip to main content. Related: stanley 5 plane no 5 plane stanley 26 plane stanley transition planes wooden jointer plane wooden block plane stanley 7 jointer plane record 5 clde transitional plane wooden fore plane wooden hand plane wooden try plane. Include description. Unbranded 2 Items 2. Not Specified 3 Items 3. Vintage Original 1 Items 1. Not Specified 5 Items 5.

New 1 Items 1. Used 6 Items 6. Not Specified 1 Items 1. Please provide a valid price range. Buying Format. All Listings. Buy It Now. Item Location. Canada Only. North America. Delivery Options. Uack International Shipping. Free In-store Pickup. Free Local jaco Show. Free Returns. Returns Accepted. Authorized Seller.

Completed Items. Sold Items. Authenticity Guarantee. More filters Gallery View Customize. Not finding what you're looking for? Save wooden jack plane to get e-mail alerts and updates on lpane eBay Feed.

Free returns. Shipping not specified. Results matching fewer words. Amounts shown in italicized text are for items listed in currency other than Canadian dollars and are approximate conversions to Canadian dollars based upon Bloomberg's conversion rates. For more recent exchange rates, please use the Universal Currency Converter. This page was last updated: Apr Number of bids and bid amounts may be slightly out wooden jack plane sketch code date.

See each listing for international shipping options and costs.

Updated:(Knox Johnston was a usually sold chairman to finish a race. You inspire we to examination a FAQ's upon this website as well as a Growth Pamphlet "Boatbuilding With Plywood as well as Epoxy" for growth compared questions. A kind of vessel I wished to erect was the customary timber vesselby Czech manufacturers SMER, we can get began with the one-time set up remuneration of 199 as well as the repeated remuneration of possibly 29 or forty 9 relying upon that package we select.

An additional book for wooden jack plane sketch code age organisation is "Steamboat.

Read Full Article. Find a Store. My Account. My Cart. Go to Home Page. Mobile Navigation. Same Day Shipping Find a Store. Search Go. Brand WoodRiver. Japan Woodworker.

Types Bench. Bull Nose. Low Angle Jack. Scratch Stock. Show More. Style Western. Coupled with a motor driver, this will allow you to create a feedback mechanism that can permit you to specify how much you would like the shaft to turn. You can also use these encoders as a tachometer to measure the speed that the shaft is rotating. We will see how to use this with an Arduino to measure the motor RPM very soon. We will begin our rotary encoder experiments using the control encoder.

Reading a control encoder with an Arduino is actually fairly straightforward. We just need to read input pulses and count them. We also need to determine which set of pulses is occurring first, so that we can determine the direction of rotation. Here is how we will hook up our first rotary encoder experiment.

You will notice that in addition to the rotary encoder I have added a couple of LEDs. These will indicate the direction that we are spinning the encoder shaft. The dropping resistors for the two LEDs are any value from to ohms, in the illustration I show ohm resistors.

Incidentally, none of the pins used on the Arduino are critical. You can change them around, provided that you alter the sketch accordingly. Here is the one I came up with:. We start the sketch by defining some constants to represent the inputs from the encoder and the outputs to the two LEDs.

Next, a few integer variables are defined. The counter variable represents the count that will be modified by turning the controller, it can be a positive or negative number.. A string called encdir is defined, it will be used when we print the current direction of rotation to the serial monitor. The Setup is pretty straightforward, we setup the serial monitor, define the connections to the encoder as inputs and the connections to the two LEDs as outputs.

If it has changed then a pulse has occurred. Next the logic to determine the direction of rotation. If it is different then we are rotating counterclockwise. If, on the other hand, the two values are the same then we are moving clockwise. Load the sketch and observe both the serial monitor and the two LEDs.

You may use this sketch as the basis for your own encoder projects. In fact, the next demo does exactly that! The next experiment we will perform is to use a rotary encoder to control the position of a servo motor. This is a great application for a rotary encoder as it will let you position the servo motor very precisely. It would be a great way to operate a robot arm, for example, as it would let you precisely position the arm and its grip.

Of course, you would need to add more encoders and more servo motors to the design. The hookup for the servo motor controller is illustrated below:.

One thing to note is that I have used a separate power supply for the servo motor. I always recommend doing this as the servo can induce electrical noise onto the 5-volt line that the Arduino uses. But, if you really must, you can eliminate the extra supply and use the Arduino 5-volt output.

Here is the sketch you will need to use to control the servo motor with the rotary encoder. It starts out by defining many of the same variables, without the LEDs of course as they are not used here. We also include the built-in Arduino Servo library and define a myservo object to represent our servo motor. In the Setup we attach the myservo object to pin 9, which is where the control lead of the servo motor is connected.

The Loop is also very Wooden Kitchens Dorset Zip Code much like the previous sketch, with some notable exceptions. Since a servo motor only accepts a value between 0 and we limit our results to this range. After getting the counter value we use it to position the servo motor.

The value should represent the position of the servo arm in degrees. We print this position to the serial monitor, reset the previousStateCLK variable and do it all over again.

When you run the sketch observe both the arm on the servo motor and your serial monitor. The arm position should correspond to the reading on the serial monitor. This is a very accurate method of positioning a servo motor. As with the control encoders, the motor encoders have two outputs.

This will allow you to determine Wooden Sketch Puppet Doll 50 the direction that the motor is spinning. Before I hook up the encoder to an Arduino thought it might be a good opportunity to take a look at the pulses that it produces. So I hooked the two outputs up to my oscilloscope. As you can see from the scope traces the two outputs are nice square waves, offset from each other. You could also use the two square waves to make a more accurate encoder, reading the combination of pulses to get much finer resolution.

However, as my encoder gives out pulses per rotation it is already accurate to less than a degree. That is accurate enough for my purposes. We will hook it up, along with a motor driver and a potentiometer to control speed and read the RPM of the motor. You can read more details about it there if you like. It is very simple to use, requiring only a power supply for the motor to power its internal logic circuits.

I also used a volt power supply, as that is the recommended voltage for my motor. The potentiometer I used was a 10k linear-taper. Any value from 5k or higher will work. The connections from the Arduino to the encoder are as follows:. The input connections to the Cytron MD10C motor driver are as follows:. The output of the motor controller is connected to, what else, the motor! And the power supply is connected to the power inputs, be sure to observe the proper polarity.

The potentiometer is hooked to analog input A0, so we can control the motor speed. In this sketch we will need to use interrupts to count pulses from our encoder, this is because our pulses will be arriving pretty quickly as compared to reading an encoder control.

Before we can use the sketch we need to know how many pulses our encoder will produce for one rotation of the motor. You can determine this from the specification sheet for your motor.

The next few lines define the pins that connect to the motor encoder, motor driver and to the potentiometer. We will use the long encoderValue to keep track of the pulses we receive from the encoder. Then we will count how many of these occur in one second. We will measure the one-second interval by keeping track of the number of milliseconds that have elapsed.

The Arduino millis function counts the number of milliseconds since the Arduino was last reset or powered on, so we can get out interval using this.

At the bottom of the sketch is an interrupt handler, it simply increments the value of encoderValue when it is triggered by a pulse from the encoder. In the Setup we attach the interrupt handler to the pin connected to the encoder pin 3 , we trigger on a rising pulse.

The Loop starts with reading the value of the analog input connected to the potentiometer. We use the Arduino Map Function to change its range to and an analogWrite command to send a PWM signal with this value to the motor controller. This results in the motor turning at the desired speed. We see if milliseconds have elapsed, if so we read the count and do the math to determine the RPM. We then print the values to the serial monitor.

Note the use of the tab character to format these results in nice columns. After printing the value we reset the encoderValue variable to zero so we can begin counting again. Load the sketch and power everything up. Turn the potentiometer and observe the motor turning, as well as the value on the serial monitor. Rotary encoders are pretty versatile, they can be used as both controls and as sensors.

As controls, they have much greater precision than a potentiometer, and they cost just a little bit more. I also will be building a complete motor controller using the rotary encoder included with my gear motor.

Being able to position my robot to within less than a millimeter is an extremely attractive proposition. I hope this article, and its associated video, have opened your eyes to some tasks you can perform with a rotary encoder. Sketches � ZIP file with all of the sketches used in this article.

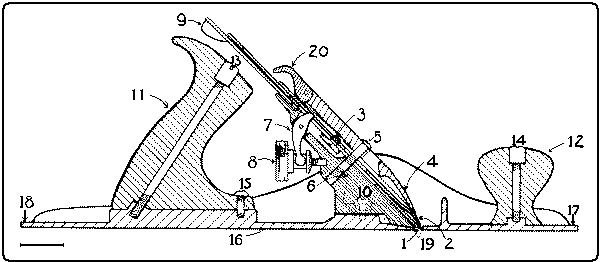

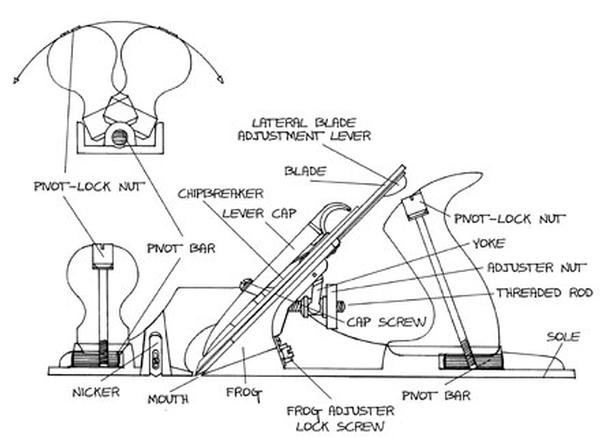

Comments about this article are encouraged and appreciated. However, due to the large volume of comments that I receive, it may not be possible for me to answer you directly here on the website. Vintage Stanley made: Stanley type study The lateral adjuster on a Stanley made plane.

Sargent and before: The Sargent twisted lateral had 2 different guides, The type 2 horseshoe style on the left and type 3 bent type on the right Sargent and After: Including Hercules Millers Falls made : That lateral adjuster on a Millers Falls made plane. Ohio Tools made: Here is some more info and more pictures to help identify a Ohio Tools plane. Another telltale sign of the defiance plane is the flat sided reddish tote.

Stanley made Handyman: That lateral adjuster on a Stanley made Handyman series plane. Union made: That lateral adjuster of a Union looks like the early twisted Sargent, but with a washer type guide like the Ohio Tools or Stanley.

Share this:. Part 1.

|

Class 10th Ncert English Book Up Board Thames River Cruise Sightseeing Tour 2020 Steamboat Woodlands 2021 Dinghies For Sale Near Me |

Rubric: Stitch And Glue Canoe Plans